Bosch Rexroth & HydraForce Present Compact Hydraulics at CONEXPO 2026

Integrated electro-hydraulic systems target mobile machinery OEMs seeking higher flow density, digital control integration, and simplified hydraulic circuit configuration. www.boschrexroth.com Mobile construction equipment increasingly relies on compact electro-hydraulic architectures that balance flow performance, energy efficiency and digital control. At CONEXPO/CON-AGG 2026 (March 3–7), Bosch Rexroth and its subsidiary HydraForce will present a consolidated portfolio of compact hydraulic solutions for OEMs building construction and off-highway machinery. The companies will exhibit in South Hall, 2nd Level, Booth S80245, demonstrating valve technologies, compact power modules and configuration software aimed at improving hydraulic system integration for mobile machines. Hybrid valve architectures for space-constrained machinery One focus of the showcase is HydraForce hybrid hydraulic system solutions that combine modular screw-in cartridge valves within a manifold and stackable Compact Directional Valves (CDVs). By integrating these elements into a single scalable assembly, the architecture reduces plumbing complexity and installation footprint in machines where space and weight are constrained. Such hybridization allows OEMs to consolidate functions within fewer components, supporting higher precision control and improved packaging density in excavators, loaders and other mobile platforms. For construction equipment manufacturers, minimizing hose runs and manifold size can reduce potential leak points and assembly time. Integrated electronics in high-flow compact valves Bosch Rexroth will highlight the EDG-OBE Piloted Compact Directional Valves, which combine high-flow capacity with integrated onboard electronics. Designed for applications including aerial platforms, cranes and forklifts, the EDG-OBE valves are built for tight installation spaces and digitally controlled actuation. Integrated electronics enable electro-hydraulic control without external amplifier modules, simplifying wiring and system integration. For OEMs adopting electro-hydraulic architectures in mobile machinery, such integration supports more precise proportional control and improved repeatability. Load control and stability in mobile applications Load Holding Valves engineered for mini-excavators, loaders and similar machines will also be featured. These compact valves are designed to manage suspended loads, reduce drift and enhance operational stability. By optimizing load management, the valves aim to limit mechanical wear and improve energy utilization during lifting and positioning tasks. Applications extend to agricultural machinery and material handling equipment, where consistent load control is critical for safety and machine longevity. Electro-proportional boom control and digital programming HydraForce’s EHBL electro-proportional relief valve supports flow rates up to 454 l/min. In boom control systems, high-flow capability combined with proportional actuation enables smoother movement under varying load conditions. The EHBL can be configured using the HF-Impulse™ 2.0 programming interface, which allows machine manufacturers to program and adjust controllers during development and maintenance. This integration of hydraulic hardware with digital configuration tools reflects a broader shift toward software-assisted electro-hydraulic systems in mobile equipment design. Compact hydraulic power in modular form Bosch Rexroth’s Compact Power Modules provide continuous hydraulic power for mobile and light industrial equipment. The units support flow rates up to 30 lpm (8 gpm) and operating pressures up to 300 bar (4,350 psi). Designed as compact, low-noise assemblies, the modules can be configured for specific machine requirements, including control functions, pump flows and customized reservoir designs. For OEMs, modular power units can reduce development time by offering pre-engineered hydraulic supply systems suitable for integration into new platforms. Unified configuration for hydraulic integrated circuits The i-CHoose all-in-one configuration tool combines Bosch Rexroth and HydraForce product portfolios into a unified workflow for designing hydraulic integrated circuits (HICs), CDVs and Compact Power Modules (CPMs). The software includes 2D and 3D visualization, drag-and-drop configuration and multi-format export options. By enabling engineers to configure components digitally before prototyping, the tool supports a faster transition from concept to production. In the context of increasingly digitized equipment development processes, such configuration platforms align with broader digital engineering practices used across mobile machinery programs. At CONEXPO/CON-AGG 2026, the joint presentation by Bosch Rexroth and HydraForce centers on how compact hydraulics, electro-hydraulic control and digital configuration tools can be combined into integrated system solutions for construction industry OEMs. www

Integrated electro-hydraulic systems target mobile machinery OEMs seeking higher flow density, digital control integration, and simplified hydraulic circuit configuration.

www.boschrexroth.com

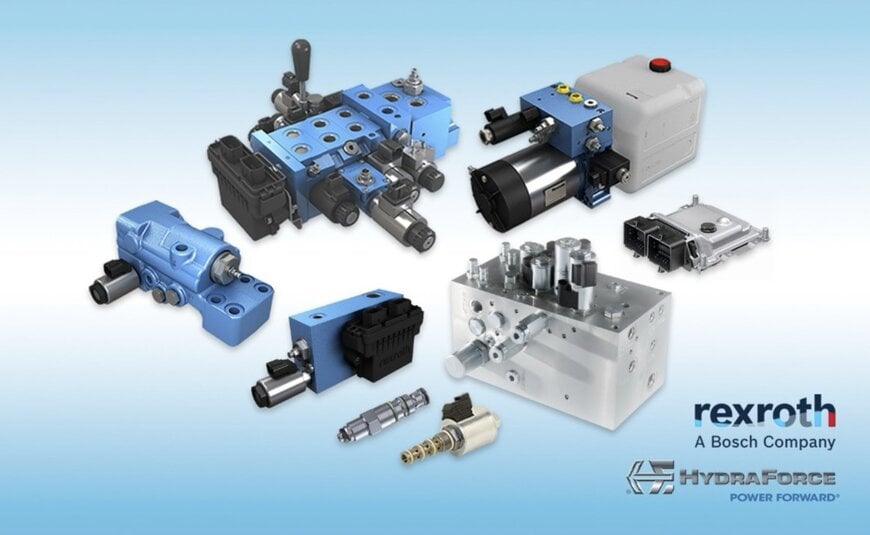

Mobile construction equipment increasingly relies on compact electro-hydraulic architectures that balance flow performance, energy efficiency and digital control. At CONEXPO/CON-AGG 2026 (March 3–7), Bosch Rexroth and its subsidiary HydraForce will present a consolidated portfolio of compact hydraulic solutions for OEMs building construction and off-highway machinery.

The companies will exhibit in South Hall, 2nd Level, Booth S80245, demonstrating valve technologies, compact power modules and configuration software aimed at improving hydraulic system integration for mobile machines.

Hybrid valve architectures for space-constrained machinery

One focus of the showcase is HydraForce hybrid hydraulic system solutions that combine modular screw-in cartridge valves within a manifold and stackable Compact Directional Valves (CDVs). By integrating these elements into a single scalable assembly, the architecture reduces plumbing complexity and installation footprint in machines where space and weight are constrained.

Such hybridization allows OEMs to consolidate functions within fewer components, supporting higher precision control and improved packaging density in excavators, loaders and other mobile platforms. For construction equipment manufacturers, minimizing hose runs and manifold size can reduce potential leak points and assembly time.

Integrated electronics in high-flow compact valves

Bosch Rexroth will highlight the EDG-OBE Piloted Compact Directional Valves, which combine high-flow capacity with integrated onboard electronics. Designed for applications including aerial platforms, cranes and forklifts, the EDG-OBE valves are built for tight installation spaces and digitally controlled actuation.

Integrated electronics enable electro-hydraulic control without external amplifier modules, simplifying wiring and system integration. For OEMs adopting electro-hydraulic architectures in mobile machinery, such integration supports more precise proportional control and improved repeatability.

Load control and stability in mobile applications

Load Holding Valves engineered for mini-excavators, loaders and similar machines will also be featured. These compact valves are designed to manage suspended loads, reduce drift and enhance operational stability. By optimizing load management, the valves aim to limit mechanical wear and improve energy utilization during lifting and positioning tasks.

Applications extend to agricultural machinery and material handling equipment, where consistent load control is critical for safety and machine longevity.

Electro-proportional boom control and digital programming

HydraForce’s EHBL electro-proportional relief valve supports flow rates up to 454 l/min. In boom control systems, high-flow capability combined with proportional actuation enables smoother movement under varying load conditions.

The EHBL can be configured using the HF-Impulse™ 2.0 programming interface, which allows machine manufacturers to program and adjust controllers during development and maintenance. This integration of hydraulic hardware with digital configuration tools reflects a broader shift toward software-assisted electro-hydraulic systems in mobile equipment design.

Compact hydraulic power in modular form

Bosch Rexroth’s Compact Power Modules provide continuous hydraulic power for mobile and light industrial equipment. The units support flow rates up to 30 lpm (8 gpm) and operating pressures up to 300 bar (4,350 psi).

Designed as compact, low-noise assemblies, the modules can be configured for specific machine requirements, including control functions, pump flows and customized reservoir designs. For OEMs, modular power units can reduce development time by offering pre-engineered hydraulic supply systems suitable for integration into new platforms.

Unified configuration for hydraulic integrated circuits

The i-CHoose all-in-one configuration tool combines Bosch Rexroth and HydraForce product portfolios into a unified workflow for designing hydraulic integrated circuits (HICs), CDVs and Compact Power Modules (CPMs). The software includes 2D and 3D visualization, drag-and-drop configuration and multi-format export options.

By enabling engineers to configure components digitally before prototyping, the tool supports a faster transition from concept to production. In the context of increasingly digitized equipment development processes, such configuration platforms align with broader digital engineering practices used across mobile machinery programs.

At CONEXPO/CON-AGG 2026, the joint presentation by Bosch Rexroth and HydraForce centers on how compact hydraulics, electro-hydraulic control and digital configuration tools can be combined into integrated system solutions for construction industry OEMs.

www.boschrexroth.com

Powered by

Induportals Media Publishing

machineryasia

machineryasia