Avoid These Mini Excavator Buying Mistakes in 2026

Save money by avoiding key mini excavator buying mistakes in 2026. Learn expert inspection tips, spot scams, and choose the right model today.

The mini excavator market has changed. If you were buying a machine five years ago, your biggest worry might have been whether to choose a Kubota or a CAT. In 2026, the landscape will be entirely different. We are looking at a market flooded with new budget imports, a rapid shift toward electrification that confuses resale values, and online marketplaces that are getting cleverer at hiding lemons. Avoid These Mini Excavator Buying Mistakes in 2026.

To navigate the complexities of the evolving market, it’s essential to understand the mini excavator buying mistakes in 2026.

This isn’t just a list of specifications; it’s a compilation of costly lessons you don’t want to experience firsthand. Whether you are a seasoned owner-operator or a landscaper buying your first unit, here is how to navigate the minefield of buying a mini excavator in 2026.

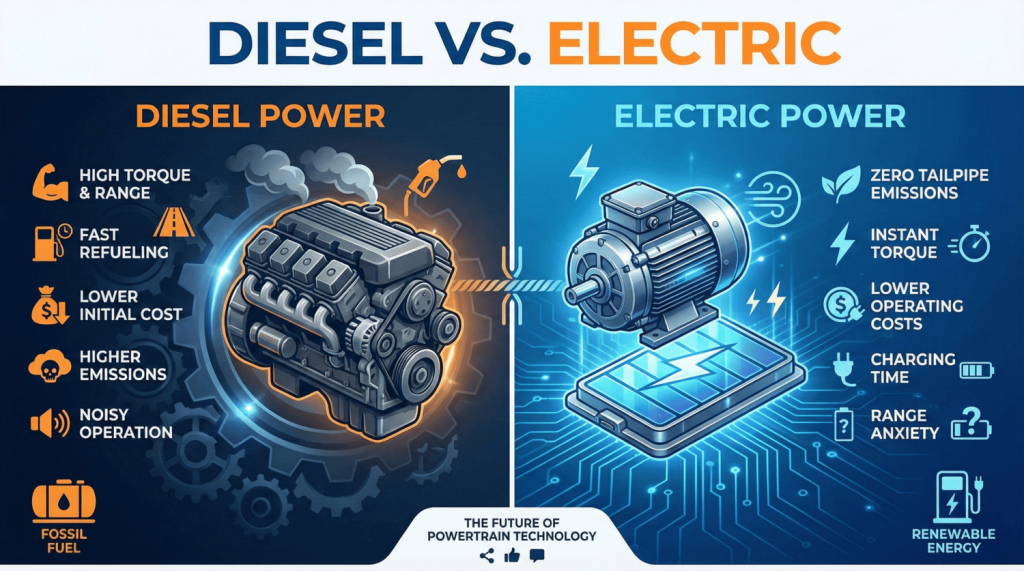

Mistake #1: Ignoring the 2026 Tech Shift (Diesel vs. Electric)

Let’s tackle the crucial issue. In 2026, electric mini excavators aren’t just expensive toys anymore; they are becoming job site requirements in some urban zones. However, the biggest mistake buyers make is jumping on—or completely ignoring—this trend without running the numbers for their specific business.

The Diesel-Only Trap

If you work primarily in residential backyards, city centers, or indoor demolition, buying a loud, diesel-belching machine might actually cost you contracts. More municipalities are enforcing noise and emission limits. I’ve seen bidders lose lucrative indoor renovation contracts simply because they couldn’t guarantee zero emissions.

The Early Adopter Trap

Conversely, don’t buy electric just because it’s trendy. If you operate in remote forestry or rural utility repair, where the closest charging infrastructure is far away, an electric unit may not be a practical choice.

- The Reality Check: Electric units generally offer lower daily operating expenses (no fuel, fewer filters), but the upfront premium is still steep.

- The 2026 Verdict: If 70% of your work is urban/indoor, test a battery-electric model. If you are hauling to remote sites, stick to a Stage V-compliant diesel.

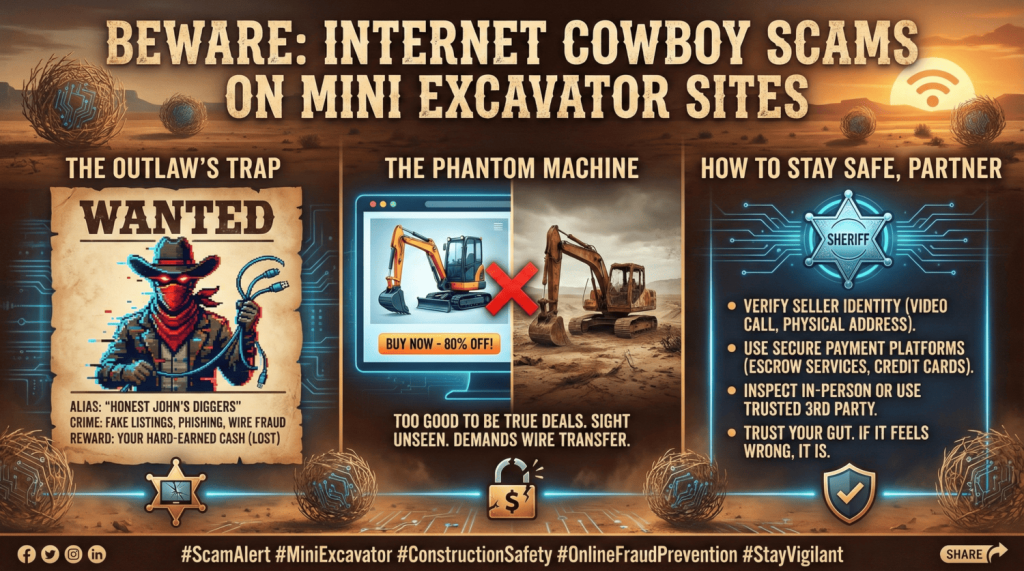

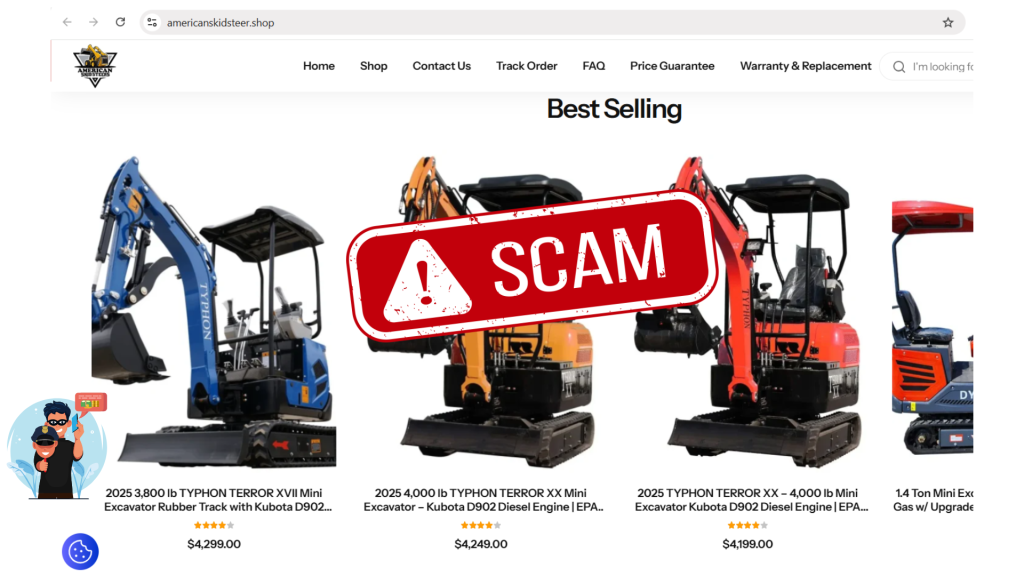

Mistake #2: Falling for the Internet Cowboy Scams

The online heavy equipment market in 2026 is wilder than ever. Scammers have moved beyond simple fake listings; they are now creating sophisticated dealer websites that look legitimate but vanish after you wire a deposit.

The Stock Photo Red Flag

If you are browsing a listing and the photos look too perfect—clean background, studio lighting—be suspicious. Real sellers take photos in the mud, in the yard, or on a trailer.

Pro Tip: Always ask for a proof of life photo. Ask the seller to send a picture of the machine with a piece of paper resting on the seat that has today’s date and your name written on it. If they make an excuse (I’m away from the yard right now), walk away.

The Generic Parts Nightmare

A massive issue in 2026 is the influx of grey market machines that look like major brands but are re-badged clones. They might run fine for a year, but when a final drive motor blows, you’ll find that no local dealer has the schematic, and the parts are on a 6-week backorder from overseas.

- The Fix: Verify the Serial Number (PIN) with a local dealer before you buy. Confirm that they can service that specific grey market model.

Mistake #3: Obsessing Over Price Tag vs. Total Cost of Ownership (TCO)

A $25,000 used mini ex might look like a steal compared to a $40,000 unit, but the purchase price is just the entry fee. The real costs are hidden in the undercarriage and hydraulics.

The Undercarriage Money Pit

Rubber tracks are consumable items, but the sprockets and idlers are expensive.

- The Inspection Test: Look at the tracks. If they are sagging more than 1–2 inches, that is an adjustment. But if you see the sprocket teeth are sharpened to points rather than being flat-topped, you are looking at a $2,000+ repair bill immediately after purchase.

Hidden Hydraulic Leaks

Don’t just look for puddles. Look for steam-cleaned areas. If an older machine has an engine bay that looks brand new and spotless, be wary. Unscrupulous sellers often pressure wash the engine to wash away evidence of slow leaks. Look for grime buildup around the clean spots—that’s where the truth hides.

Mistake #4: Misunderstanding Auxiliary Flow (The Attachment Heartbreak)

In 2026, a mini excavator is the most versatile machine on the jobsite. You aren’t just digging holes; you’re running augers, breakers, brush cutters, and thumbs. The most painful mistake I see? Purchasing a machine that does not have the necessary flow rate to operate your tools is the most common mistake I observe.

The High-Flow Confusion

Just because a machine has auxiliary lines doesn’t mean it can run a forestry mulcher.

- Scenario: You buy a 3-ton excavator to clear brush. You spend $5,000 on a mulching head. You hook it up, and the mulcher stalls every time it hits a branch.

- The Cause: Your machine pumps 15 gallons per minute (GPM), but the mulcher requires 20 GPM at high pressure.

The Lesson: Verify the GPM (gallons per minute) and PSI (pressure) ratings of the machine’s auxiliary circuit. Do not guess. If you plan to run heavy hydromechanical tools, you might need a machine with a dedicated high-flow package

Mistake #5: Buying the Maximum Size You Can Afford (Transport Logistics)

It’s tempting to believe that a larger size is always better. Why buy a 3.5-ton machine when you can get a 5-ton for a little more?

This is primarily due to the inability to tow the machine.

The Towing Trap

Transport laws are strict. A 3.5-ton mini excavator can often be towed behind a heavy-duty pickup truck (like an F-250 or 3500) on a standard bumper-pull trailer. Once you jump to a 5-ton or 6-ton machine, you are often pushing into CDL (Commercial Driver’s License) territory depending on your region’s Gross Combined Weight Rating (GCWR) laws.

- The Consequence: You buy a 5-ton beast, then realize you need to buy a $60,000 dump truck and get a CDL just to move it to a job site 10 miles away.

- Action Step: Check your truck’s towing capacity and your local towing regulations before you choose the machine size.

machineryasia

machineryasia