The Ultimate Guide to Buying a 3 Ton Mini Excavator: Specs, Prices, and Why It’s the King of Compact

Sometimes, the ability to perform multiple tasks and reach them more effectively is more crucial than possessing a large amount of raw power. This is precisely why the 3 ton mini excavator class is one of the most popular in the construction and landscaping industries.

A 3 ton excavator is often called the Goldilocks machine because it fits perfectly in the middle of the compact range. It is much stronger than the smaller 1-ton micro diggers made for doorways, but it is still simple to move and use compared to bigger 5-ton or 8-ton mid-size machines.

But there is a reason the 3 ton class (roughly 6,000 to 8,000 lbs) is the fastest-growing segment in the heavy equipment industry. The 3 ton class falls into the ideal range. It is powerful enough to dig swimming pools and trench utilities but compact enough to squeeze through side yards and legal enough to tow behind a heavy-duty pickup truck without needing a Commercial Driver’s License (CDL) in many jurisdictions.

Whether you are a seasoned contractor looking to expand your fleet or a property owner tired of renting, this guide breaks down everything you need to know about purchasing, maintaining, and optimizing a 3-ton mini excavator in 2026.

1. Defining the Beast: What Actually Counts as a 3 Ton Machine?

Before you commit to a purchase, you need to understand the specs. In the industry, 3 ton is a loose term. You will often see model numbers like “30,” “35,” or “33.”

Here is the technical breakdown of what you are actually buying in this class:

- Operating Weight: Typically between 6,000 lbs (2,700 kg) and 8,500 lbs (3,800 kg). This weight includes the machine, a standard bucket, a full tank of fuel, and an operator.

- Horsepower: Most models hover between 24 HP and 25 HP.

- Why this number matters: Manufacturers intentionally keep engines just under 25 HP to avoid strict EPA Tier 4 Final emission regulations that require complex DEF (Diesel Exhaust Fluid) systems and particulate filters. This makes 3-ton machines easier and cheaper to maintain than their 5-ton big brothers.

- Dig Depth: Expect a standard dig depth of 9 to 11 feet. This is the magic number for sewer lines and septic systems.

2. The Zero Tail Swing Revolution

In the old days, the counterweight at the back of the excavator hung far off the tracks. If you swung the cab around to dump dirt, the rear end would swing out and smash into fences, walls, or (heaven forbid) your truck.

Why ZTS is a Deal-Breaker Feature:

- Urban Work: If you are working next to a house foundation, ZTS allows you to rotate 360 degrees without the rear of the machine ever protruding beyond the width of the tracks.

- Safety: It significantly reduces the risk of crushing accidents for workers standing near the machine.

- Resale Value: In 2026, it is very difficult to resell a conventional tail swing machine in the compact class. ZTS is what everyone wants.

3. Under the Hood: Hydraulics and Breakout Force

You aren’t buying an engine; you are buying a hydraulic pump. The engine just spins the pump; the pump does the actual work. When analyzing listings, stop looking at horsepower and start looking at hydraulic flow rate (GPM) and breakout force.

Hydraulic Flow (GPM)

For a 3 ton machine, you should look for a flow rate of 15 to 20 gallons per minute (GPM) regarding the auxiliary hydraulics.

- Low Flow: If the machine only puts out 10 GPM, it will struggle to run attachments. A brush cutter will stall, and an auger won’t have the torque to drill through clay.

- High Flow: Higher flow means smoother operation. It allows you to lift the boom, curl the bucket, and swing the cab all at the same time without the machine “choking” or slowing down.

Bucket Breakout Force

This is the measurement of how hard the machine can curl the bucket to rip through roots or hardpan soil.

- Target Metric: Look for a breakout force of at least 6,000 to 7,000 lbf. Anything less, and you will find yourself frustrated when you hit rocky soil.

4. Attachments: The Multiplier Effect

The smartest operators know that the excavator arm is just a Swiss Army Knife holder. To get the maximum ROI (return on investment) from your 3 ton mini excavator for sale, you need to budget for attachments.

Don’t just buy a digging bucket. Here is the essential loadout for this weight class:

Must-Have: The Hydraulic Thumb

If there is one piece of advice you take from this post, let it be this: Do not buy an excavator without a thumb.

- A thumb opposes the bucket, allowing you to grab and pick up objects.

- Without a thumb, you are just digging holes.

- With a thumb: You are clearing land, stacking retaining walls, moving logs, and demolishing concrete. A thumb increases the machine’s utility by 300%.

The Profit Attachments

- Auger Drive: For drilling fence posts and deck footings. A 3-ton machine can handle auger bits up to 24 inches wide.

- Hydraulic Breaker (Hammer): Essential for demolition. Breaking up an old driveway pays very well per hour.

- Tilt-Rotator or Tilt-Coupler: These allow you to angle the bucket sideways to grade slopes and ditches without moving the tracks. It’s an advanced feature, but it’s becoming standard for high-end landscaping.

5. New vs. Used: Where Is the Value?

This is the most common debate. Should you spend $65,000 on a brand-new name brand or $35,000 on a used unit or an import?

Buying New (Name Brand)

- Pros: Warranty protection (usually 2-3 years), dealer support, highest resale value, financing deals (often 0% APR).

- Cons: High upfront cost, immediate depreciation the moment it leaves the lot.

Buying Import/Direct-to-Consumer

Brands like TYPHON and other emerging manufacturers are disrupting the market by offering brand-new 3 ton machines at the price of used ones.

- Pros: Incredible value for money. You get a new engine and new hydraulics for a fraction of the cost.

- Cons: Parts availability can sometimes be slower (though this is improving rapidly), and resale value is currently lower than legacy brands.

- Verdict: If you are a DIYer, a farmer, or a small contractor who can do basic maintenance, these machines offer the best “bang for your buck.”

Buying Used

- The Risk: A used mini excavator is a gamble. If the previous owner didn’t grease the pins daily, you are looking at a “sloppy” bucket that shakes and rattles.

- The Undercarriage Check: When inspecting a used 3 ton mini excavator for sale, look at the sprocket teeth (the gear that drives the track).

- Good: Teeth have flat tops.

- Bad: Teeth are sharp and pointed. This means the undercarriage is worn out and will cost you $2,500+ to replace immediately.

6. Transportability: The Hidden Cost Saver

A 5-ton excavator requires a CDL driver and a massive dump truck or gooseneck trailer to move. A 3 ton excavator breaks down like this:

- Machine Weight: ~7,500 lbs

- Trailer Weight: ~2,500 lbs (Heavy Duty Equipment Trailer)

- Total Towing Load: ~10,000 lbs

Most modern ¾ ton pickups (Ford F-250, Chevy 2500, Ram 2500) and even some properly equipped ½ ton trucks can legally tow this load. This means you don’t need to hire a haulage company every time you move jobs. You have total independence.

7. Cabin Comfort: Canopy vs. Cab

Do you need an enclosed cab with A/C?

- The Canopy (ROPS): It’s an open station with a roof.

- Pros: Cheaper, better visibility, easy to hop in and out of (great for utility work where you are constantly checking depths).

- Cons: You are exposed to dust, rain, heat, and bees.

- The Enclosed Cab: Sealed glass with HVAC.

- Pros: You can work in the rain and snow. It keeps dust out of your lungs. It’s a radio-friendly environment.

- Cons: Glass breaks and is expensive to replace. On hot days, if the A/C breaks, it turns into a greenhouse.

Pro Tip: If you live in a northern climate, the enclosed cab increases resale value significantly. No one wants to sit in an open canopy in 20-degree weather.

8. Maintenance: How to Keep it Alive Forever

Any mechanic will tell you: Grease is cheap; steel is expensive.

Maintaining a 3 ton mini excavator is surprisingly simple, provided you are disciplined.

- Daily: Grease every pivot point. Most 3 ton machines have about 15-20 grease zerks. It takes 5 minutes. Do it every morning.

- Weekly: Check track tension. Rubber tracks stretch. If they are too loose, they will “de-track” (fall off) when you turn in soft mud, which is a nightmare to fix in the field.

- 500 Hours: Change engine oil and fuel filters.

- Hydraulic Fluid: Keep an eye on the sight glass. If the fluid looks milky, water has gotten in. Water destroys hydraulic pumps.

9. Financing and ROI

For many businesses, the purchase price isn’t the hurdle—it’s the cash flow. Fortunately, financing for heavy equipment is very accessible right now.

- ROI Calculation: If you rent a 3-ton excavator, it costs roughly $350 – $500 per day.

- If you buy a machine for roughly $800/month in financing payments, you only need to use the machine for two days a month to break even compared to renting.

- Everything after day two is pure profit (minus fuel and maintenance).

This math is why so many landscapers are transitioning from renting to owning.

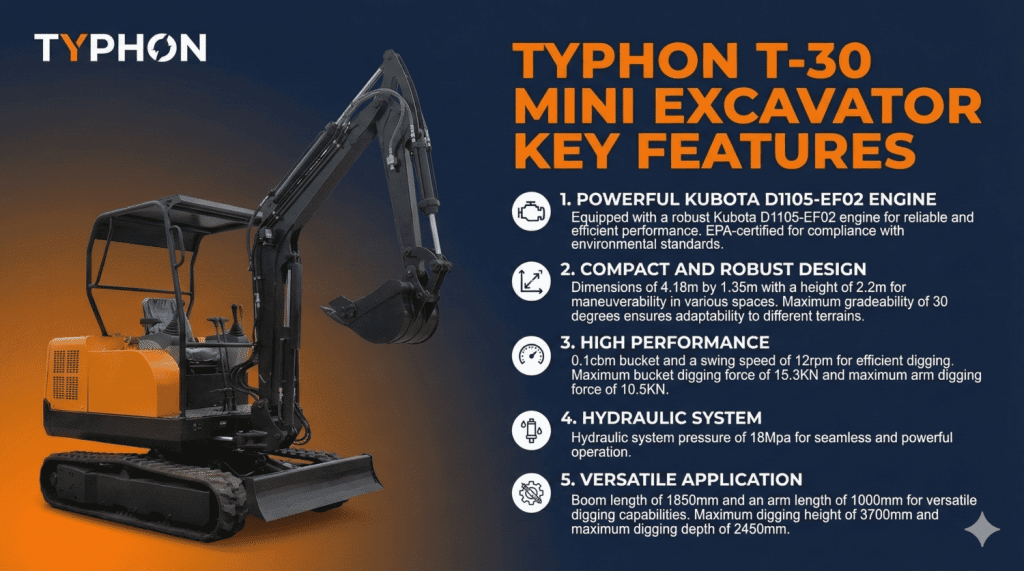

Brand Focus: The Rise of TYPHON Machinery

In the past, your only option was spending $60,000+ buying a risky used unit. Enter TYPHON Machinery, a brand that has disrupted the market by combining American reliability standards with aggressive pricing.

If you are looking for a 3 ton mini excavator for sale, the TYPHON TERROR T-30 (and its siblings like the X2) is frequently cited as the Value King.

Why TYPHON Is Winning the 3-Ton Market:

- The Engine Trust Factor: The TYPHON T-30 3 ton model is powered by the Kubota D1105-EF02.

- Why this matters: Many buyers fear import machines because of the engine. TYPHON uses a genuine Kubota diesel engine—the exact same engine found in machines that cost twice as much. This means any local diesel mechanic can service it, and parts are available at any NAPA or tractor supply store.

- Price vs. Performance: While legacy brands charge $55k-$70k, TYPHON’s 3 ton class models often retail between $24,000 and $36,000.

- Standard Features: TYPHON often includes the hydraulic thumb and an enclosed cabin (sometimes with A/C) as standard or low-cost options, whereas big brands charge thousands extra for these luxuries.

machineryasia

machineryasia