Sleipner Unveils Fully Electric and Autonomous Transport System for Mines

Sleipner has unveiled a fully electric and autonomous transport system for moving mining and construction equipment. Aimed at mines that already use automated equipment and therefore have the infrastructure to support autonomous solutions, the new transport system currently has several patents pending. The world premiere of the new emission-free transport system took place at the […] Sleipner Unveils Fully Electric and Autonomous Transport System for Mines published on The HeavyQuip Magazine.

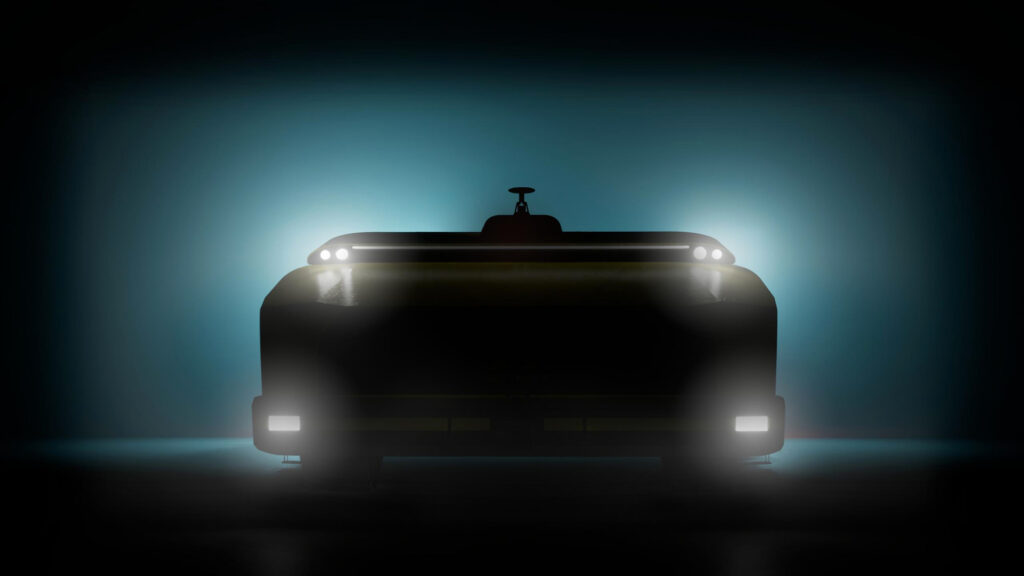

Sleipner has unveiled a fully electric and autonomous transport system for moving mining and construction equipment. Aimed at mines that already use automated equipment and therefore have the infrastructure to support autonomous solutions, the new transport system currently has several patents pending. The world premiere of the new emission-free transport system took place at the Electric Mining 2024 event in Perth, Australia. The first deliveries are planned for 2026.

Emissions and life cycle costs significantly reduced

Autonomous mining requires all equipment to be automated – from the giant vehicles that transport blasted rocks and the drills. The entire site can be operated and monitored remotely and safely without mining personnel having to work among the automated vehicles.

“There are already dozens of autonomous mines around the world, and more are coming all the time. Australia is one of the pioneers. Currently, the big mining companies are the driving force in autonomous mining, in part due to their emission reduction targets. By 2030, the goal among mining companies is to reduce their carbon dioxide emissions by half and at the same time automate operations as much as possible. We want to be a pioneer in this development and a market leader in mobilization solutions.”

said Jukka Koponen, CEO of Sleipner Finland.

The new transport system that has been unveiled by Sleipner is battery-powered, which enables the use of renewable energy for the autonomous transport of mining and construction equipment.

“Our new transport system makes it possible to eliminate carbon dioxide emissions completely when transporting equipment, whereas current solutions consume significant amounts of diesel. In the future, it will be possible to move machines with battery-powered, environmentally friendly solutions. At the same time, the productivity of the equipment being transported will also improve by about 5%, while life cycle costs will decrease by up to 10%.”

said Teijo Höylä, CTO at Sleipner Finland.

A big step forward for the electrification of mines

The company says that the new autonomous and electric transport system will be scaled to different weight classes, and the autonomous control system interface will be brand independent.

“The autonomous and electric transport system can also be connected to the ecosystems of other OEMs since it has an open interface. Versatility and future needs have been taken into account in the design. The transport system can be used to transport, for example, drills, bulldozers and also battery packs at mines. In this way, battery power can be provided on a large scale, which helps in the electrification of mines and the efficient operation of battery-powered equipment.”

said Höylä.

Like all other Sleipner products, the new lowbed trailer is designed to operate reliably in temperatures ranging from -40 to +50 degrees Celsius, which is taken into account in the high-quality materials and components. Components from well-known manufacturers are also used, ensuring that maintenance is as smooth as possible globally.

Improved working conditions and reduced labor shortages

In addition to reducing emissions, the automation of mines is also a solution to the prevailing labor shortages in the sector. Technological advances also have an impact on occupational well-being due to changing job descriptions.

“Finding sufficient personnel for mines is a global challenge. Automated machines and equipment, such as our new transport system, enable mines to be operated by remote control. In this way, personnel do not have to be exposed to dust and vibration, which improves their wellbeing. Similarly, personnel do not have to work in the field among large machines, which increases safety. If a worker needs to enter the area, all activities must be stopped completely within a certain safety radius. Automated equipment, on the other hand, can work with each other with only certain limitations.”

explained Höylä.

Source: Sleipner

Sleipner Unveils Fully Electric and Autonomous Transport System for Mines published on The HeavyQuip Magazine.

machineryasia

machineryasia