Develon Excavators Deliver High-Output, Low-Fuel Mining in Estonia

Heavy tracked excavators operating in an Estonian oil shale mine demonstrate high utilisation rates and comparatively low fuel consumption under continuous, demanding extraction conditions. na.develon-ce.com Heavy oil shale mining in northeastern Estonia places sustained mechanical and operational demands on equipment, with machines expected to operate for long shifts in abrasive ground conditions. At a site located roughly 100 kilometres from the Russian border, large tracked excavators and wheel loaders supplied under the Develon brand are being used for continuous extraction and material handling with limited downtime. The mine, operated by KKT Oil OÜ, deploys two DX1000LC-7 excavators and one DX800LC-7 as its primary production machines, supported by a DX490LC-7 and a DL480-7 wheel loader for loading crushed material. Together, the three largest excavators have accumulated more than 50,000 operating hours over four years, averaging approximately 5,000 hours per machine annually. Individual machine hour counts underline the intensity of use: one DX800LC-7 has exceeded 20,200 operating hours, while the two DX1000LC-7 units have recorded approximately 15,500 and 2,300 hours respectively. The DX490LC-7, with more than 16,200 hours logged, is equipped with a hydraulic breaker to access harder sections of the oil shale deposit. The two DX1000LC-7 excavators are fitted with 5.5 m³ rock buckets and extract material directly without the need for blasting. Depending on ground conditions, the DX800LC-7 alternates between a standard bucket and a hydraulic vibrating ripper to loosen harder material before loading. This flexibility allows production to continue across varying geological conditions within the mine. Operational reliability has been a key factor for the site, with the excavators typically working between 15 and 20 hours per day without major technical interruptions. According to the operator, fuel consumption has also played a significant role in fleet selection. Under site conditions, the DX800LC-7 records an average fuel consumption of around 35 litres per hour, while the larger DX1000LC-7 averages approximately 42 litres per hour. Support for the fleet is provided by INTRAC Estonia, the authorised dealer for Develon equipment in Estonia, Latvia, and Lithuania. Alongside machine availability and fuel efficiency, service responsiveness has been cited as a contributing factor to maintaining high utilisation rates in a continuous mining environment. The deployment illustrates how large excavators configured for direct extraction can sustain long operating hours in oil shale mining while controlling operating costs through fuel efficiency and reduced reliance on blasting. www.develon-ce.com Powered by Induportals Media Publishing

Heavy tracked excavators operating in an Estonian oil shale mine demonstrate high utilisation rates and comparatively low fuel consumption under continuous, demanding extraction conditions.

na.develon-ce.com

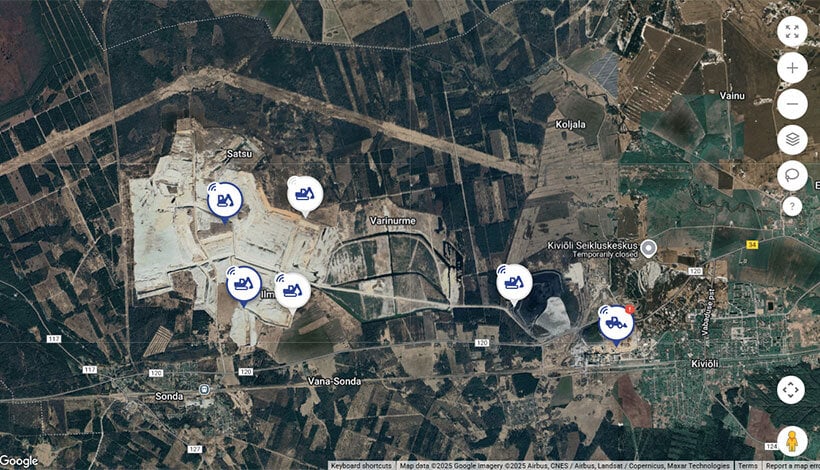

Heavy oil shale mining in northeastern Estonia places sustained mechanical and operational demands on equipment, with machines expected to operate for long shifts in abrasive ground conditions. At a site located roughly 100 kilometres from the Russian border, large tracked excavators and wheel loaders supplied under the Develon brand are being used for continuous extraction and material handling with limited downtime.

The mine, operated by KKT Oil OÜ, deploys two DX1000LC-7 excavators and one DX800LC-7 as its primary production machines, supported by a DX490LC-7 and a DL480-7 wheel loader for loading crushed material. Together, the three largest excavators have accumulated more than 50,000 operating hours over four years, averaging approximately 5,000 hours per machine annually.

Individual machine hour counts underline the intensity of use: one DX800LC-7 has exceeded 20,200 operating hours, while the two DX1000LC-7 units have recorded approximately 15,500 and 2,300 hours respectively. The DX490LC-7, with more than 16,200 hours logged, is equipped with a hydraulic breaker to access harder sections of the oil shale deposit.

The two DX1000LC-7 excavators are fitted with 5.5 m³ rock buckets and extract material directly without the need for blasting. Depending on ground conditions, the DX800LC-7 alternates between a standard bucket and a hydraulic vibrating ripper to loosen harder material before loading. This flexibility allows production to continue across varying geological conditions within the mine.

Operational reliability has been a key factor for the site, with the excavators typically working between 15 and 20 hours per day without major technical interruptions. According to the operator, fuel consumption has also played a significant role in fleet selection. Under site conditions, the DX800LC-7 records an average fuel consumption of around 35 litres per hour, while the larger DX1000LC-7 averages approximately 42 litres per hour.

Support for the fleet is provided by INTRAC Estonia, the authorised dealer for Develon equipment in Estonia, Latvia, and Lithuania. Alongside machine availability and fuel efficiency, service responsiveness has been cited as a contributing factor to maintaining high utilisation rates in a continuous mining environment.

The deployment illustrates how large excavators configured for direct extraction can sustain long operating hours in oil shale mining while controlling operating costs through fuel efficiency and reduced reliance on blasting.

www.develon-ce.com

Powered by

Induportals Media Publishing

machineryasia

machineryasia