wirtgen group introduces MOBIREX MR 130(i) PRO

The powerful impact crusher for a wide variety of applications: Thanks to its robust crushing unit with two impact toggles and versatile rotor ledge configurations, the MOBIREX MR 130(i) PRO delivers a very high quality product. The 8.4 m² large optional double-deck post screening unit makes it possible to produce two classified final grain sizes with a single machine - without the use of an additional screening machine. Different configuration options here make all the difference. Examples of configuration options for the double-deck post screening unit Two final grain sizes in concrete recycling The impact crusher is loaded with a feed size of 0–400 mm. The post screening unit of the MR 130(i) PRO is equipped with screen surfaces in the upper and lower deck. Two defined final grain sizes, which are often used for recycling soil, can therefore be discharged via the middle grain conveyor and the fine grain conveyor. The oversize grain is returned to the crushing process via the oversize grain conveyor. One final grain size in asphalt recycling The impact crusher is loaded with a smaller feed size of 0–100 mm. The middle grain conveyor is not in operation during this application. The special feature: the middle grain can be returned to the crushing process on a reversible transfer conveyor via the oversize grain conveyor. The post screening unit is equipped in the upper and lower deck with a screen surface, whereby the upper deck guarantees an extended screening surface and a thinner layer covering because it is equipped with a slightly larger screen surface than the lower deck. It therefore functions as a relief deck and the complete screening surface of the double-deck post screening unit is utilised. One final grain size in limestone The MR 130(i) PRO is loaded with a feed material of size 0–600 mm. The post screening unit is only equipped with a screen surface in the upper deck. The lower deck is not covered and the opening to the transfer conveyor is sealed by a rubber element. A defined final grain size is discharged, the oversize grain is added to the crushing process via the oversize grain conveyor. www.wirtgen-group.com Powered by Induportals Media Publishing

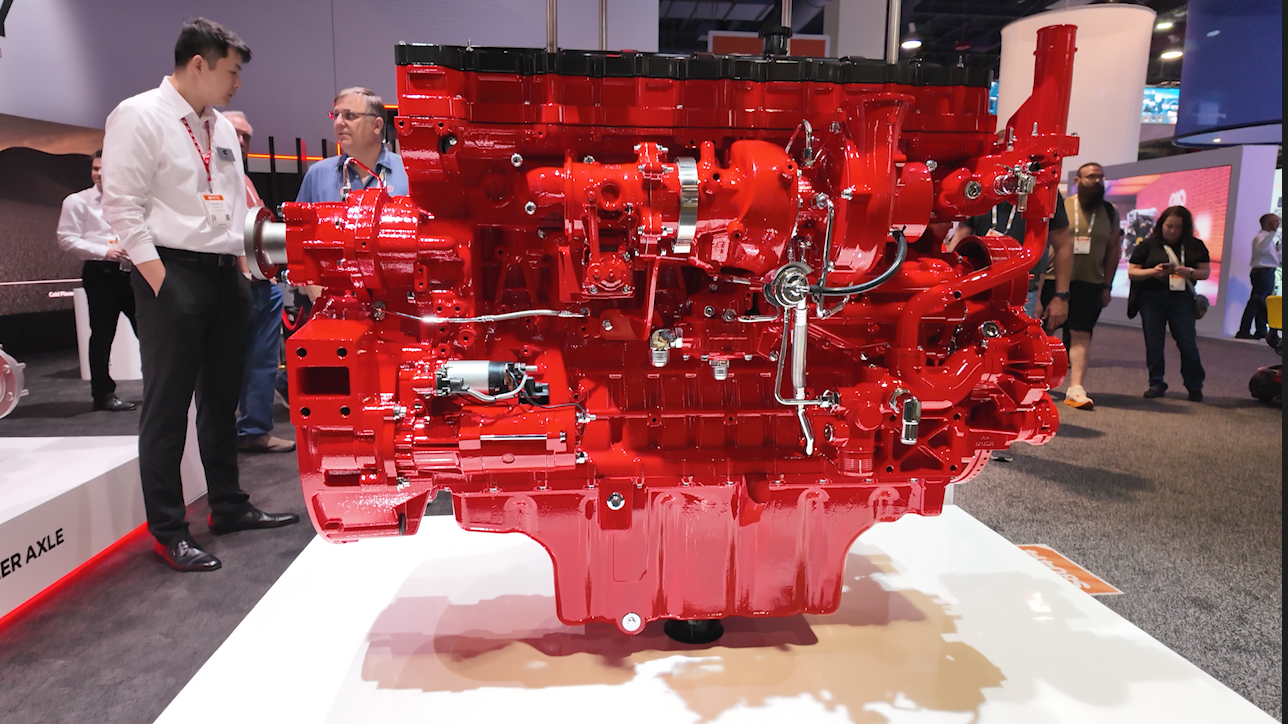

The powerful impact crusher for a wide variety of applications: Thanks to its robust crushing unit with two impact toggles and versatile rotor ledge configurations, the MOBIREX MR 130(i) PRO delivers a very high quality product.

The 8.4 m² large optional double-deck post screening unit makes it possible to produce two classified final grain sizes with a single machine - without the use of an additional screening machine. Different configuration options here make all the difference.

Examples of configuration options for the double-deck post screening unit

Two final grain sizes in concrete recycling

The impact crusher is loaded with a feed size of 0–400 mm. The post screening unit of the MR 130(i) PRO is equipped with screen surfaces in the upper and lower deck. Two defined final grain sizes, which are often used for recycling soil, can therefore be discharged via the middle grain conveyor and the fine grain conveyor. The oversize grain is returned to the crushing process via the oversize grain conveyor.

One final grain size in asphalt recycling

The impact crusher is loaded with a smaller feed size of 0–100 mm. The middle grain conveyor is not in operation during this application. The special feature: the middle grain can be returned to the crushing process on a reversible transfer conveyor via the oversize grain conveyor. The post screening unit is equipped in the upper and lower deck with a screen surface, whereby the upper deck guarantees an extended screening surface and a thinner layer covering because it is equipped with a slightly larger screen surface than the lower deck. It therefore functions as a relief deck and the complete screening surface of the double-deck post screening unit is utilised.

One final grain size in limestone

The MR 130(i) PRO is loaded with a feed material of size 0–600 mm. The post screening unit is only equipped with a screen surface in the upper deck. The lower deck is not covered and the opening to the transfer conveyor is sealed by a rubber element. A defined final grain size is discharged, the oversize grain is added to the crushing process via the oversize grain conveyor.

www.wirtgen-group.com

Powered by

Induportals Media Publishing

machineryasia

machineryasia