Volvo Completely Redesigns its Articulated Dump Trucks, Adds 50-Ton Model

“This is our biggest and boldest articulated launch ever,” says CEO of the seven new models with payloads of 28 to 61 tons.

Six months after unleashing its biggest excavator redesign in 20 years, Volvo is back at it – this time unveiling a complete overhaul of its articulated dump trucks, including a brand-new size for the company.

The seven models of the company’s next-generation ADTs range in payload from 28 to 61 U.S. tons and will replace the current lineup.

The unveiling January 28 also revealed a new size for Volvo with the 50-ton A50, a 5-ton boost in payload over the 45-ton A45G FS. It also delivers an 8% increase in fuel efficiency over the A45G.

Calling it the company’s “biggest launch year ever,” Volvo Construction Equipment President and CEO Melker Jernberg said, “This is our biggest and boldest articulated launch ever.”

Volvo plans to begin taking orders in North America for the new A35, A40, A45 and A50 models in the first quarter, with the remaining three to be released throughout 2025. The other models in the lineup are the A25, A30 and A60.

Along with increased fuel efficiency over their predecessors, the new artics get a redesigned, more comfortable cab, lots of new technology for easier operation, increased operator visibility to the surroundings, a host of new safety features and easier access to maintenance points, the company says. The trucks were also built with low-carbon steel and "can be adapted for future drivetrain technologies," according to Volvo.

The A50 represents a new size articulated dump truck for Volvo.Volvo CE

The A50 represents a new size articulated dump truck for Volvo.Volvo CE

Fully Redesigned Cab

Volvo increase the floor area of the next-gen ADTs’ cabs, reduced noise level and added new hanging pedals, steering wheel and adjustable seat. A premium seat comes with heating and air and automatically adjusts air suspension to the operator’s weight.

The hood was redesigned for a lower slope and the window panels are larger for better operator visibility. The artics get a Volvo Co-Pilot touchscreen for viewing their surroundings with standard entrance camera and optional front and rear cameras.

Starting the trucks also got easier and safer. A ground-level startup button lights up the stairs to the cab and boots up controls. The operator turns the key when in the cab to crank up the engine. The key also shuts down the truck, with no need to push the ground-level button.

Volvo CE

Volvo CE

Other features for the cab:

- Repositioned door and railings on both sides.

- Focused lighting on the stairs and platform.

- Ergonomic levers and switch layouts.

- Additional LED lighting.

- Wider windshield wiper coverage.

- Bluetooth connectivity.

- USB ports for charging devices.

Loaded with Tech

Next-generation Volvo A40Volvo CE

Next-generation Volvo A40Volvo CE

The Volvo Co-Pilot display has been updated to easier control of such functions as camera settings, climate control and machine status, the company says. Features on the previous models that were controlled by switches are now done by touchscreen. The other screen is an instrument cluster in front of the steering wheel.

Other technology for helping the operator include:

- Haul Assist with on-board weighing, which provides real-time payload data to prevent overloading and minimize carry back. This also reduces fuel consumption and machine wear, the company says.

- Connected Map – a positioning service that provides a visual overview for all machines and vehicles on a jobsite for operators and the office via a cloud-based online portal.

- Performance Indicator – provides a digital visual overview of production, fuel efficiency and machine cycle data via real-time dashboard.

- ActiveCare Direct telematics.

Volvo notes that the software is designed “to incorporate future upgrades and smart solutions.”

Raising Efficiency, Productivity

Volvo CE

Volvo CE

Other features to aid efficiency and productivity:

- Volvo Dynamic Drive – “offers predictive gear selection that adapts to operating conditions, and a downhill speed control function.”

- New frame and body designed to increase tipping clearance and material flow when dumping.

- Reinforced axles for handling heavier loads and higher torque.

- Optional overhung tailgate that has longer arms for “a quicker and wider opening when dumping.”

- 100% differential locks.

- Hydro-mechanical steering.

- All-terrain bogie.

Maintenance Assistance

An access ladder hidden under the hood folds out for performing maintenance.Equipment World

An access ladder hidden under the hood folds out for performing maintenance.Equipment World

Other new maintenance features:

- Access ladder hidden under the hood that folds out for performing maintenance.

- Hood can be raised or lowered with the push of a button, and the entire engine compartment is illuminated.

- Condenser package has been moved to the right side of the cab.

- Harness anchor points on the cab for safety when washing windows and other tasks.

- Electronic fuel-filter priming system, which replaces manual priming.

Quick Specs

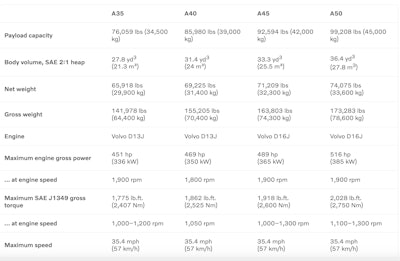

Volvo provided the following spec chart for the four new articulated dump trucks slated for North America, with three more to be released later in the year:

Volvo CE

Volvo CE

machineryasia

machineryasia