Liebherr & Yaskawa Implement Fully Autonomous Welding Cell

A robot-based production system at Liebherr’s Telfs plant automates handling and welding of bulldozer track roller frames to increase output and process consistency. www.yaskawa.eu.com Steel construction, heavy machinery manufacturing, and robotic welding increasingly face pressure to raise output, ensure consistent quality, and offset skilled labor shortages. At its Telfs (Tyrol) plant, Liebherr has taken a significant step in automation by introducing a fully autonomous production cell for bulldozer track roller frames, developed and implemented by Yaskawa. From manual welding to autonomous production The new production cell marks the first time Liebherr has fully automated the manufacturing of complete, complex steel component assemblies at this site. Previously, the track roller frames were manually positioned and welded. The new system automates all handling, positioning, joining, and removal processes, enabling continuous, unmanned operation. The solution targets medium-volume production of highly integrated steel components, with approximately 500 units per year per variant, while ensuring reproducible welding quality and process stability. Cell layout and process integration The autonomous manufacturing cell combines four integrated workstations within a footprint of approximately 22 × 8 meters. Two welding stations are equipped with arc-welding robots that perform tack welding and final welding in defined sequences. A handling station supplies all required components, which include laser-cut parts, castings, and raw materials with varying tolerances. Finished components are removed via a dedicated unloading station. A central handling robot mounted on a ground track supplies both welding stations, automatically changing grippers to accommodate different component geometries. Pre-buffering and integrated safety systems allow the cell to operate fully automatically, enabling unmanned production during night shifts. Robotics and hardware configuration The welding operations are carried out by arc-welding robots designed for large steel components, supported by positioners and turntables capable of handling loads up to 10,000 kg. A high-payload handling robot manages component logistics within the cell, while an overhead portal system removes finished assemblies. The system also integrates welding power sources, torch technology, sensors, extraction and filtration equipment, and safety systems into a single automated environment. All mechanical components, including tracks, positioners, and portals, were supplied as part of the integrated solution. Productivity gains and operational impact Since commissioning in autumn 2025, the automated cell has achieved a production increase of more than 50 percent compared with the previous manual process. In addition to higher output, the system improves weld consistency, reduces manual handling, and supports Liebherr’s long-term strategy of maintaining in-house steel construction expertise despite labor market constraints. Automation as a scalability enabler By automating the complete manufacturing sequence for complex steel assemblies, the project demonstrates how integrated robotics can support scalable production in heavy machinery manufacturing. The solution serves as a reference for applying autonomous welding cells to medium-volume, high-complexity steel construction. www.yaskawa.com Powered by Induportals Media Publishing

A robot-based production system at Liebherr’s Telfs plant automates handling and welding of bulldozer track roller frames to increase output and process consistency.

www.yaskawa.eu.com

Steel construction, heavy machinery manufacturing, and robotic welding increasingly face pressure to raise output, ensure consistent quality, and offset skilled labor shortages. At its Telfs (Tyrol) plant, Liebherr has taken a significant step in automation by introducing a fully autonomous production cell for bulldozer track roller frames, developed and implemented by Yaskawa.

From manual welding to autonomous production

The new production cell marks the first time Liebherr has fully automated the manufacturing of complete, complex steel component assemblies at this site. Previously, the track roller frames were manually positioned and welded. The new system automates all handling, positioning, joining, and removal processes, enabling continuous, unmanned operation.

The solution targets medium-volume production of highly integrated steel components, with approximately 500 units per year per variant, while ensuring reproducible welding quality and process stability.

Cell layout and process integration

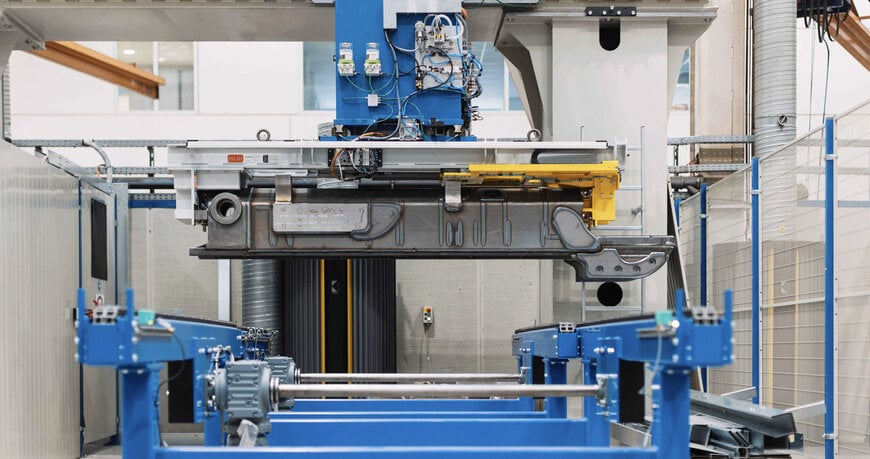

The autonomous manufacturing cell combines four integrated workstations within a footprint of approximately 22 × 8 meters. Two welding stations are equipped with arc-welding robots that perform tack welding and final welding in defined sequences. A handling station supplies all required components, which include laser-cut parts, castings, and raw materials with varying tolerances. Finished components are removed via a dedicated unloading station.

A central handling robot mounted on a ground track supplies both welding stations, automatically changing grippers to accommodate different component geometries. Pre-buffering and integrated safety systems allow the cell to operate fully automatically, enabling unmanned production during night shifts.

Robotics and hardware configuration

The welding operations are carried out by arc-welding robots designed for large steel components, supported by positioners and turntables capable of handling loads up to 10,000 kg. A high-payload handling robot manages component logistics within the cell, while an overhead portal system removes finished assemblies.

The system also integrates welding power sources, torch technology, sensors, extraction and filtration equipment, and safety systems into a single automated environment. All mechanical components, including tracks, positioners, and portals, were supplied as part of the integrated solution.

Productivity gains and operational impact

Since commissioning in autumn 2025, the automated cell has achieved a production increase of more than 50 percent compared with the previous manual process. In addition to higher output, the system improves weld consistency, reduces manual handling, and supports Liebherr’s long-term strategy of maintaining in-house steel construction expertise despite labor market constraints.

Automation as a scalability enabler

By automating the complete manufacturing sequence for complex steel assemblies, the project demonstrates how integrated robotics can support scalable production in heavy machinery manufacturing. The solution serves as a reference for applying autonomous welding cells to medium-volume, high-complexity steel construction.

www.yaskawa.com

Powered by

Induportals Media Publishing

machineryasia

machineryasia