Liebherr delivers BHP’s first electric excavator

The R 9400 E has also been equipped with Liebherr’s autonomous cable reel system to ensure optimal mobility of the excavator on site. www.liebherr.com At the beginning of 2024, Liebherr-Australia commissioned an R 9400 E 400-tonne class electric excavator for BHP at its Western Australia Iron Ore Yandi mine. This excavator is the first electric excavator in BHP’s worldwide fleet. Liebherr-Australia and BHP recently celebrated the commissioning of the first electric excavator to join the BHP fleet: an R 9400 E. The 400-tonne class backhoe excavator was delivered to BHP’s Western Australia Iron Ore Yandi mine, located in Western Australia’s Pilbara region. This R 9400 E is also equipped with Liebherr’s cable reel – an autonomous cable management solution for Liebherr’s electric excavators that offers improved machine manoeuvrability and operator safety. Due to the dynamic and versatile nature of iron ore mining compared to traditional cable electric excavator applications, the added mobility offered by the cable reel will help maintain optimal productivity during operation. ‘Liebherr, as a company, has more than 40 years’ experience in the development and manufacturing of electric excavators, so electrification is part of our DNA,’ says Brian Boitano, executive general manager, sales and marketing, Liebherr-Australia. ‘In fact, we are excited to be expanding the reach of this technology into the Australian market. We’ve had multiple orders for electric excavators this year, with several electric excavators on our order books for 2024 and 2025.’ Partner for success For two decades, Liebherr and BHP have enjoyed a strong and successful partnership based on shared values of safety, innovation and a commitment to delivering high-quality solutions that drive the mining industry forward. ‘The R 9400 E is a testament to Liebherr’s dedication to providing innovative and efficient zero emission solutions for the mining sector. We are thrilled to partner with BHP to introduce our proven electric excavators into their operations,’ continues Boitano. This milestone highlights Liebherr's role as a trusted partner and solutions provider within the mining sector. Liebherr’s ability to offer proven zero emission solutions – such as its range of electric excavators – to its customers is vital as the industry moves rapidly towards zero emissions. ‘We’ve set ourselves a clear goal to hit net zero operational greenhouse gas emissions by 2050,’ says Tim Day, asset president, Western Australia Iron Ore. ‘In order to get there, we’re working to electrify most of our mining fleet that currently runs on diesel. Having BHP's first electric excavator at Yandi is exciting and the trial is another step forward on our pathway to net zero. Liebherr is a great company and a great partner, and we are delighted to be working with them on such an important project.’ www.liebherr.com Powered by Induportals Media Publishing

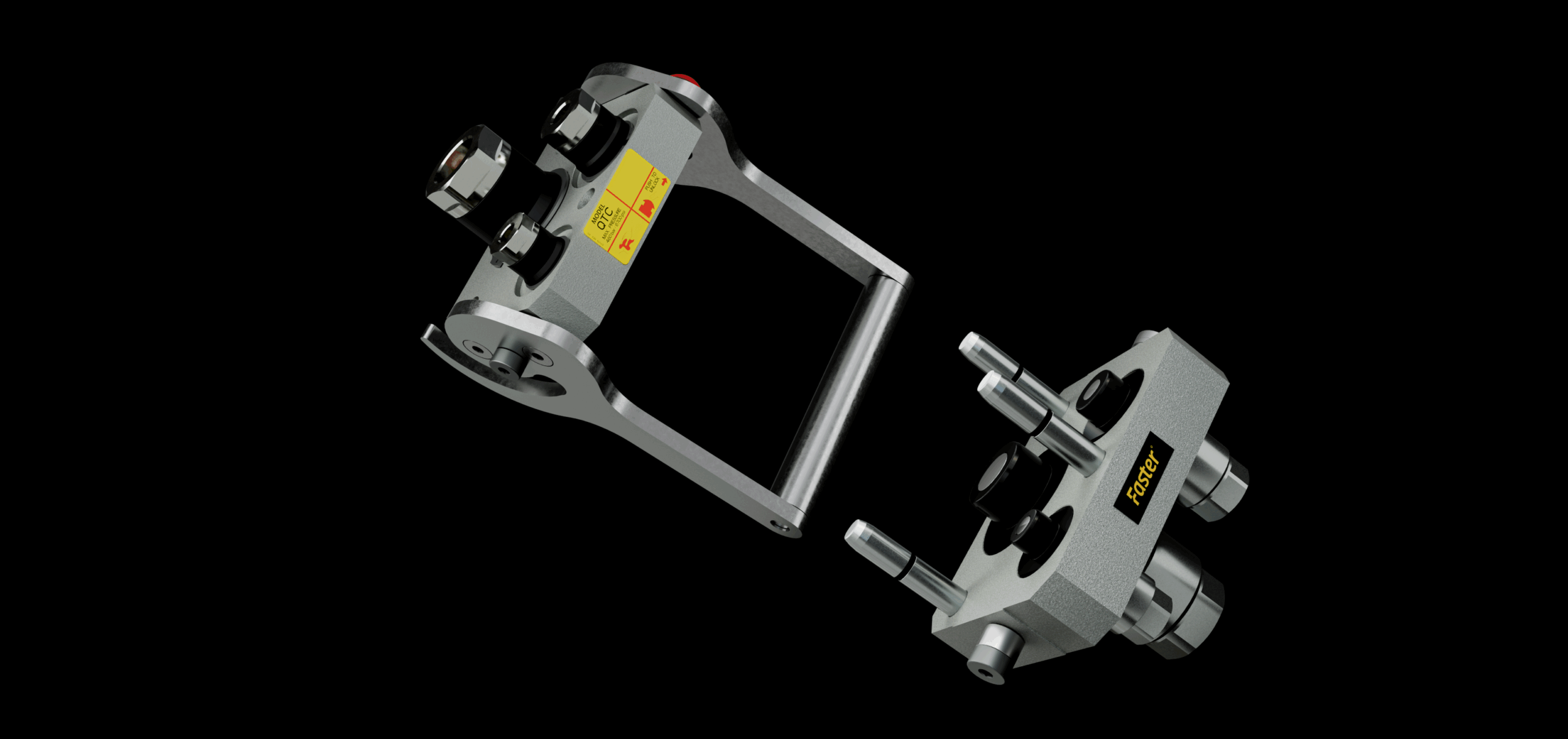

The R 9400 E has also been equipped with Liebherr’s autonomous cable reel system to ensure optimal mobility of the excavator on site.

www.liebherr.com

At the beginning of 2024, Liebherr-Australia commissioned an R 9400 E 400-tonne class electric excavator for BHP at its Western Australia Iron Ore Yandi mine. This excavator is the first electric excavator in BHP’s worldwide fleet.

Liebherr-Australia and BHP recently celebrated the commissioning of the first electric excavator to join the BHP fleet: an R 9400 E. The 400-tonne class backhoe excavator was delivered to BHP’s Western Australia Iron Ore Yandi mine, located in Western Australia’s Pilbara region.

This R 9400 E is also equipped with Liebherr’s cable reel – an autonomous cable management solution for Liebherr’s electric excavators that offers improved machine manoeuvrability and operator safety. Due to the dynamic and versatile nature of iron ore mining compared to traditional cable electric excavator applications, the added mobility offered by the cable reel will help maintain optimal productivity during operation.

‘Liebherr, as a company, has more than 40 years’ experience in the development and manufacturing of electric excavators, so electrification is part of our DNA,’ says Brian Boitano, executive general manager, sales and marketing, Liebherr-Australia. ‘In fact, we are excited to be expanding the reach of this technology into the Australian market. We’ve had multiple orders for electric excavators this year, with several electric excavators on our order books for 2024 and 2025.’

Partner for success

For two decades, Liebherr and BHP have enjoyed a strong and successful partnership based on shared values of safety, innovation and a commitment to delivering high-quality solutions that drive the mining industry forward.

‘The R 9400 E is a testament to Liebherr’s dedication to providing innovative and efficient zero emission solutions for the mining sector. We are thrilled to partner with BHP to introduce our proven electric excavators into their operations,’ continues Boitano.

This milestone highlights Liebherr's role as a trusted partner and solutions provider within the mining sector. Liebherr’s ability to offer proven zero emission solutions – such as its range of electric excavators – to its customers is vital as the industry moves rapidly towards zero emissions.

‘We’ve set ourselves a clear goal to hit net zero operational greenhouse gas emissions by 2050,’ says Tim Day, asset president, Western Australia Iron Ore. ‘In order to get there, we’re working to electrify most of our mining fleet that currently runs on diesel. Having BHP's first electric excavator at Yandi is exciting and the trial is another step forward on our pathway to net zero. Liebherr is a great company and a great partner, and we are delighted to be working with them on such an important project.’

www.liebherr.com

Powered by

Induportals Media Publishing

machineryasia

machineryasia