Intelligent Awareness Systems for Automated Heavy Equipment Safety

Leica Geosystems introduces the Xsight360 system, using edge-based AI and 360-degree cameras to provide real-time hazard detection and proactive safety intelligence for heavy equipment. leica-geosystems.com The launch of the Leica Xsight360 safety awareness solution across the United States and Canada establishes a new technical benchmark for situational awareness in the heavy construction sector. This system utilizes edge-based artificial intelligence (AI) and high-resolution visual sensors to detect hazards, providing a foundational layer for the modern digital supply chain in construction by transforming raw jobsite data into proactive safety strategies. Edge-AI and Real-Time Hazard Detection At the core of the portfolio is the Leica Xsight360, which utilizes up to six ruggedized onboard cameras to provide a 360-degree field of vision around heavy machinery. The system is powered by the Leica CRS360 processor, which runs advanced convolutional neural networks trained on over 700,000 hours of real-world construction data. This high-capacity processing allows for the real-time detection of people, vehicles, and construction cones with low latency, issuing immediate audio and visual alerts via the Leica CRS214 in-cabin display. The hardware is engineered for the rigors of the automotive data ecosystem, using automotive Ethernet cables with M12 connectors and quick-connect plugs to facilitate easy installation on machines that undergo frequent assembly and disassembly. Calibration is streamlined through factory pre-sets and an automated IP assignment process, eliminating the need for traditional checkerboard calibration tools. Automated Intervention and 3D Avoidance A critical component of the expanded portfolio is the dynamic 3D Avoidance Zone system, developed in collaboration with Xwatch Safety Solutions. This technology integrates directly into the Leica MC1 machine control software, allowing operators to import three-dimensional coordinates of hazardous areas, such as high-voltage power lines or underground utilities. Unlike passive warning systems, this solution provides active machine intervention. When an excavator or other equipment approaches a defined avoidance zone, the system automatically interfaces with the machine’s hydraulics to slow or stop movement before an incursion occurs. This mechanism ensures that precision machine control and safety protocols are embedded directly into the operational workflow. Cloud-Based Analytics and Compliance The transition from reactive to proactive safety is managed through a cloud-based safety intelligence platform. Incident data and video footage are transmitted via the Leica CR50 communication unit to the cloud, where agentic AI models generate safety dashboards and incident heatmaps. Technical safety managers utilize these tools to: Audit Policy Compliance: AI assistants compare video footage against site-specific safety protocols to automatically flag violations. Generate Safety Indexes: Metrics such as the ratio of "danger hours" to operating hours allow for objective benchmarking of safety performance over time. Automate Reporting: The system can generate "Heads Up!" training videos and compliance reports in minutes, facilitating immediate feedback loops for site crews. Integration with Personal Alert Systems The portfolio further incorporates the Leica iCON PA10 and PA80 personal alert systems. These wearables use Peer-to-Peer (P2P) communication to establish a 50-meter detection radius around machinery. When a pedestrian wearing a tag enters a machine's proximity, both the operator and the pedestrian receive synchronized visual, audible, and vibratory alerts. By integrating these sensors into the broader Leica ConX cloud solution, site managers gain a comprehensive view of all machine-to-people and machine-to-object interactions across the jobsite. www.leica-geosystems.com Powered by Induportals Media Publishing

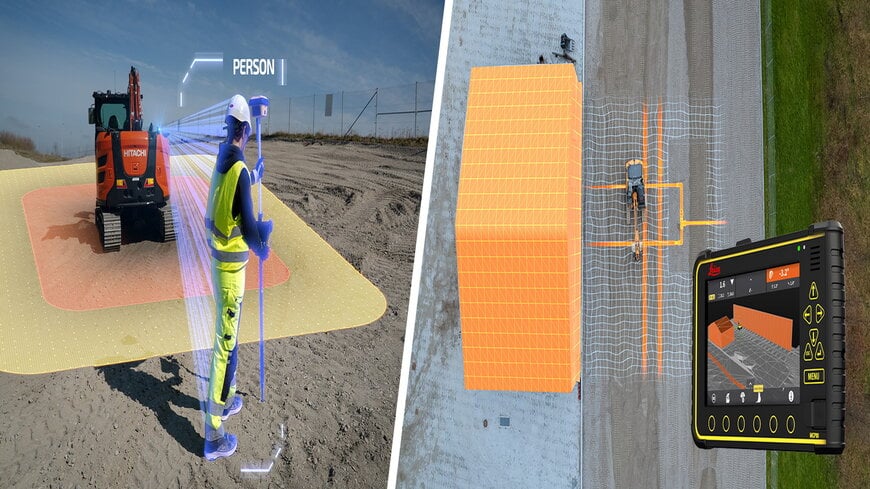

Leica Geosystems introduces the Xsight360 system, using edge-based AI and 360-degree cameras to provide real-time hazard detection and proactive safety intelligence for heavy equipment.

leica-geosystems.com

The launch of the Leica Xsight360 safety awareness solution across the United States and Canada establishes a new technical benchmark for situational awareness in the heavy construction sector. This system utilizes edge-based artificial intelligence (AI) and high-resolution visual sensors to detect hazards, providing a foundational layer for the modern digital supply chain in construction by transforming raw jobsite data into proactive safety strategies.

Edge-AI and Real-Time Hazard Detection

At the core of the portfolio is the Leica Xsight360, which utilizes up to six ruggedized onboard cameras to provide a 360-degree field of vision around heavy machinery. The system is powered by the Leica CRS360 processor, which runs advanced convolutional neural networks trained on over 700,000 hours of real-world construction data. This high-capacity processing allows for the real-time detection of people, vehicles, and construction cones with low latency, issuing immediate audio and visual alerts via the Leica CRS214 in-cabin display.

The hardware is engineered for the rigors of the automotive data ecosystem, using automotive Ethernet cables with M12 connectors and quick-connect plugs to facilitate easy installation on machines that undergo frequent assembly and disassembly. Calibration is streamlined through factory pre-sets and an automated IP assignment process, eliminating the need for traditional checkerboard calibration tools.

Automated Intervention and 3D Avoidance

A critical component of the expanded portfolio is the dynamic 3D Avoidance Zone system, developed in collaboration with Xwatch Safety Solutions. This technology integrates directly into the Leica MC1 machine control software, allowing operators to import three-dimensional coordinates of hazardous areas, such as high-voltage power lines or underground utilities.

Unlike passive warning systems, this solution provides active machine intervention. When an excavator or other equipment approaches a defined avoidance zone, the system automatically interfaces with the machine’s hydraulics to slow or stop movement before an incursion occurs. This mechanism ensures that precision machine control and safety protocols are embedded directly into the operational workflow.

Cloud-Based Analytics and Compliance

The transition from reactive to proactive safety is managed through a cloud-based safety intelligence platform. Incident data and video footage are transmitted via the Leica CR50 communication unit to the cloud, where agentic AI models generate safety dashboards and incident heatmaps.

Technical safety managers utilize these tools to:

- Audit Policy Compliance: AI assistants compare video footage against site-specific safety protocols to automatically flag violations.

- Generate Safety Indexes: Metrics such as the ratio of "danger hours" to operating hours allow for objective benchmarking of safety performance over time.

- Automate Reporting: The system can generate "Heads Up!" training videos and compliance reports in minutes, facilitating immediate feedback loops for site crews.

The portfolio further incorporates the Leica iCON PA10 and PA80 personal alert systems. These wearables use Peer-to-Peer (P2P) communication to establish a 50-meter detection radius around machinery. When a pedestrian wearing a tag enters a machine's proximity, both the operator and the pedestrian receive synchronized visual, audible, and vibratory alerts. By integrating these sensors into the broader Leica ConX cloud solution, site managers gain a comprehensive view of all machine-to-people and machine-to-object interactions across the jobsite.

www.leica-geosystems.com

Powered by

Induportals Media Publishing

machineryasia

machineryasia