HITACHI BEGINS FEASIBILITY TRIAL OF THE WORLD'S FIRST ULTRA-LARGE FULL BATTERY DUMP TRUCK

The technological feasibility trial is being conducted at First Quantum’s Kansanshi deep open-pit copper-gold mine, one of the company's largest mine in Zambia. www.hitachicm.com Full battery dump truck in operation at a Zambian mine site Hitachi Construction Machinery announced the commencement of the world's first technological feasibility trial of an ultra-large full battery rigid frame dump truck by an Original Equipment Manufacturer (“OEM”) operating at First Quantum Minerals Ltd. Kansanshi copper and gold mine in the Republic of Zambia. The technological feasibility trial, which began in June 2024, is being conducted at First Quantum’s Kansanshi deep open-pit copper-gold mine, one of the company's largest mine in Zambia. The technological feasibility trial aims to verify the basic performance of operations required of a battery-powered dump truck – such as traveling, turning, and stopping – under actual operating loads, as well as the verification of battery charging and discharging cycles. First Quantum are leaders in trolley system operations with in-house technology development and deployment, and at their Kansanshi copper and gold mine can provide Hitachi Construction Machinery with the infrastructure and facilities that are needed to test a full battery dump truck, such as proven overhead dynamic charging solutions and variety of haul circuits in an actual operational mining environment. The use of Kansanshi infrastructure and the collaboration with First Quantum are the key differentiators, to fast tracking this evolving technology design which makes it the ideal practical and commercially viable solution. Further to this, renewable energy accounts for 92% of Zambia’s energy, and in addition to hydroelectric power generation, solar, wind, biogas, and other power sources from First Quantum are expected to be scaled up in the future. The challenge of achieving true decarbonization is underway in Zambia, a country with abundant renewable energy requirements and will help Hitachi Construction Machinery to leverage this technology trial to further product development and broader applicational studies with customers around the world, thereby helping them to achieve their zero emissions goals. The full battery dump truck was jointly developed with ABB, a technology leader in electrification and automation. Based on Hitachi Construction Machinery's extensive experience with dump trucks equipped with trolley dynamic charging systems, the full battery dump truck is able to continuously operate practically in sites, by directly charging from the overhead lines and regenerative braking system without needing to stop and charging through the adoption of the battery system developed by ABB. In addition, limiting the battery volume reduces the battery weight as a percentage of the overall vehicle weight and helps maximize the load capacity to display a high level of cost performance. Features of the dynamic charging battery dump truck being jointly developed: 1. Controls the initial and lifecycle costs By drawing the electrical power from the dynamic charging system required during operation will limit the volume of batteries on the trucks, providing a sustainable solution. In addition, the system aims to reduce the lifecycle costs and environmental impact through life cycle assessment by drawing electrical power from the overhead system while connected, simultaneously charging the battery in an appropriate manner to reduce the load and depth of discharge, maximizing battery life. 2.Reduces the vehicle weight and maximizes the load capacity Limiting the battery volume lessens the weight of the battery solution on the vehicle, maximizing the battery dump truck’s payload capacity. 3. Dynamic charging solution to provide a higher rate of operation over static charging The solution draws electrical power from the dynamic charging system during operation while simultaneously charging the battery, removing the need to stop the vehicle for recharging. Therefore, achieving a higher rate of continuous operation to maintain productivity at site. www.hitachicm.com Powered by Induportals Media Publishing

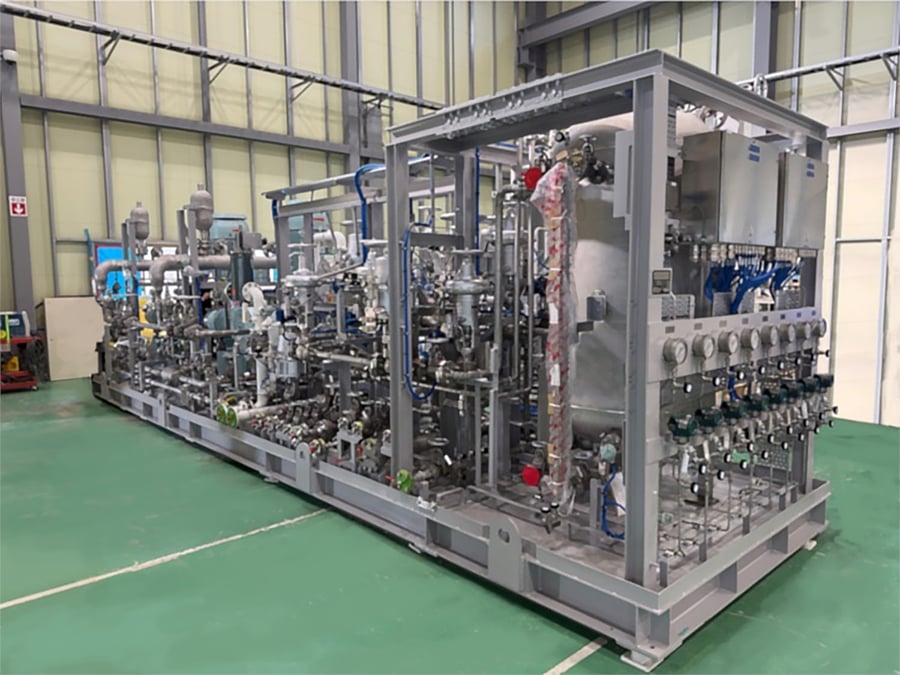

The technological feasibility trial is being conducted at First Quantum’s Kansanshi deep open-pit copper-gold mine, one of the company's largest mine in Zambia.

www.hitachicm.com

Hitachi Construction Machinery announced the commencement of the world's first technological feasibility trial of an ultra-large full battery rigid frame dump truck by an Original Equipment Manufacturer (“OEM”) operating at First Quantum Minerals Ltd. Kansanshi copper and gold mine in the Republic of Zambia.

The technological feasibility trial, which began in June 2024, is being conducted at First Quantum’s Kansanshi deep open-pit copper-gold mine, one of the company's largest mine in Zambia. The technological feasibility trial aims to verify the basic performance of operations required of a battery-powered dump truck – such as traveling, turning, and stopping – under actual operating loads, as well as the verification of battery charging and discharging cycles.

First Quantum are leaders in trolley system operations with in-house technology development and deployment, and at their Kansanshi copper and gold mine can provide Hitachi Construction Machinery with the infrastructure and facilities that are needed to test a full battery dump truck, such as proven overhead dynamic charging solutions and variety of haul circuits in an actual operational mining environment. The use of Kansanshi infrastructure and the collaboration with First Quantum are the key differentiators, to fast tracking this evolving technology design which makes it the ideal practical and commercially viable solution.

Further to this, renewable energy accounts for 92% of Zambia’s energy, and in addition to hydroelectric power generation, solar, wind, biogas, and other power sources from First Quantum are expected to be scaled up in the future. The challenge of achieving true decarbonization is underway in Zambia, a country with abundant renewable energy requirements and will help Hitachi Construction Machinery to leverage this technology trial to further product development and broader applicational studies with customers around the world, thereby helping them to achieve their zero emissions goals.

The full battery dump truck was jointly developed with ABB, a technology leader in electrification and automation. Based on Hitachi Construction Machinery's extensive experience with dump trucks equipped with trolley dynamic charging systems, the full battery dump truck is able to continuously operate practically in sites, by directly charging from the overhead lines and regenerative braking system without needing to stop and charging through the adoption of the battery system developed by ABB. In addition, limiting the battery volume reduces the battery weight as a percentage of the overall vehicle weight and helps maximize the load capacity to display a high level of cost performance.

Features of the dynamic charging battery dump truck being jointly developed:

1. Controls the initial and lifecycle costs

By drawing the electrical power from the dynamic charging system required during operation will limit the volume of batteries on the trucks, providing a sustainable solution. In addition, the system aims to reduce the lifecycle costs and environmental impact through life cycle assessment by drawing electrical power from the overhead system while connected, simultaneously charging the battery in an appropriate manner to reduce the load and depth of discharge, maximizing battery life.

2.Reduces the vehicle weight and maximizes the load capacity

Limiting the battery volume lessens the weight of the battery solution on the vehicle, maximizing the battery dump truck’s payload capacity.

3. Dynamic charging solution to provide a higher rate of operation over static charging

The solution draws electrical power from the dynamic charging system during operation while simultaneously charging the battery, removing the need to stop the vehicle for recharging. Therefore, achieving a higher rate of continuous operation to maintain productivity at site.

Powered by

Induportals Media Publishing

machineryasia

machineryasia