Schaeffler is driving electrification and sustainability in the construction equipment industry

Schaeffler presents its construction machinery product range: friction-optimized bearings, Ewellix linear actuators as a hydraulic alternative, sensors, and efficient 800V electric motors for maximum energy savings. www.schaeffler.com At bauma 2025 in Munich, Schaeffler will highlight how technological innovations and optimizations contribute to making the construction equipment industry more sustainable and efficient. In addition to the electrification of drives and operating functions, the Motion Technology Company also relies on the consistent use of low-friction rolling bearings and sensors. The objective is to further increase the efficiency of construction equipment and reduce TCO (total cost of ownership). Electrification – one of the keys to decarbonization Schaeffler's initiatives for the construction equipment industry are focused on the electrification of construction equipment. Patrick Scherr, Global Sector Lead Offroad in the Bearings & Industrial Solutions division at Schaeffler, on the business unit’s goals: “We want to provide our customers with products and technologies that make motion smarter, cleaner, and safer. With our innovative and comprehensive product portfolio, we are a future-oriented supplier for construction equipment manufacturers.” High-performance electric motors for off-road applications Schaeffler's portfolio of electric motors covers all common voltage ranges up to 800 V. Schaeffler offers electric drives with a maximum continuous power output of 300 kW designed specifically for the construction equipment sector. The drives are extremely efficient with high power densities, making them a key enabler for the transition to electric mobility and a significant contributor to the reduction of CO₂ emissions. A highlight at the Schaeffler booth in Munich will be electric motors with a maximum speed of 10,500 rpm and a continuous power output of 219 kW. The oil-cooled motors offer an exceptionally high efficiency rate of > 97% over a wide speed range and have been specially developed for heavy-duty applications. Precisely controllable and efficient: Ewellix electromechanical linear actuators Schaeffler offers modular, highly efficient electromechanical linear actuators for both operating functions and the automated operation of flaps and engine hoods. The series cover nominal forces from 1.5 to 150 kN and travel ranges from 300 to 2,000 mm and are designed for small excavators, wheel loaders, and mobile work platforms, among other applications. Precise control, synchronous movement of several cylinders, and energy recovery can be realized. They also offer lower TCO over the service life of a construction machine due to their very long maintenance intervals. Contributing to global sustainability with low-friction rolling bearings Low-friction rolling bearings from Schaeffler already offer the potential for energy savings and a reduction in TCO. Among these are tapered roller bearings with optimized rib contact and a further improved raceway surface structure. Significant savings can be achieved with optimized high-performance bearings in hydraulic motors and pumps in wheel loaders, for example. Extrapolated to 1,000 construction machines with eight hours of operating time, the annual savings potential is around 26,000 MWh, which corresponds to the average annual energy consumption of more than 6,500 three-person households. www.schaeffler.com Powered by Induportals Media Publishing

Schaeffler presents its construction machinery product range: friction-optimized bearings, Ewellix linear actuators as a hydraulic alternative, sensors, and efficient 800V electric motors for maximum energy savings.

www.schaeffler.com

At bauma 2025 in Munich, Schaeffler will highlight how technological innovations and optimizations contribute to making the construction equipment industry more sustainable and efficient. In addition to the electrification of drives and operating functions, the Motion Technology Company also relies on the consistent use of low-friction rolling bearings and sensors. The objective is to further increase the efficiency of construction equipment and reduce TCO (total cost of ownership).

Electrification – one of the keys to decarbonization

Schaeffler's initiatives for the construction equipment industry are focused on the electrification of construction equipment. Patrick Scherr, Global Sector Lead Offroad in the Bearings & Industrial Solutions division at Schaeffler, on the business unit’s goals: “We want to provide our customers with products and technologies that make motion smarter, cleaner, and safer. With our innovative and comprehensive product portfolio, we are a future-oriented supplier for construction equipment manufacturers.”

High-performance electric motors for off-road applications

Schaeffler's portfolio of electric motors covers all common voltage ranges up to 800 V. Schaeffler offers electric drives with a maximum continuous power output of 300 kW designed specifically for the construction equipment sector. The drives are extremely efficient with high power densities, making them a key enabler for the transition to electric mobility and a significant contributor to the reduction of CO₂ emissions.

A highlight at the Schaeffler booth in Munich will be electric motors with a maximum speed of 10,500 rpm and a continuous power output of 219 kW. The oil-cooled motors offer an exceptionally high efficiency rate of > 97% over a wide speed range and have been specially developed for heavy-duty applications.

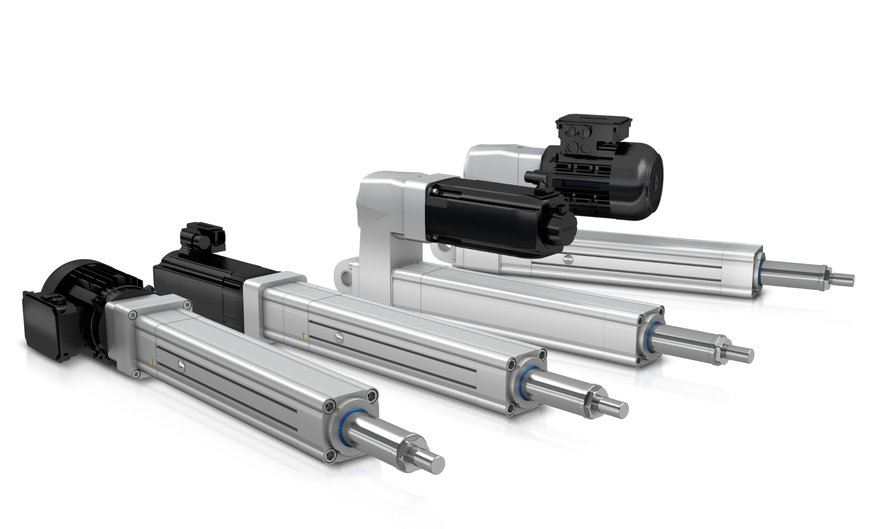

Precisely controllable and efficient: Ewellix electromechanical linear actuators

Schaeffler offers modular, highly efficient electromechanical linear actuators for both operating functions and the automated operation of flaps and engine hoods. The series cover nominal forces from 1.5 to 150 kN and travel ranges from 300 to 2,000 mm and are designed for small excavators, wheel loaders, and mobile work platforms, among other applications. Precise control, synchronous movement of several cylinders, and energy recovery can be realized. They also offer lower TCO over the service life of a construction machine due to their very long maintenance intervals.

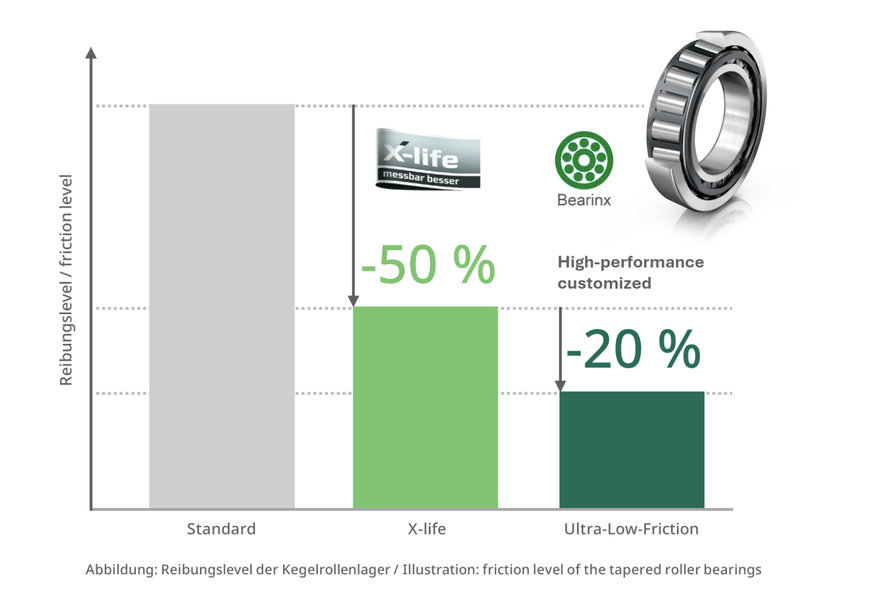

Contributing to global sustainability with low-friction rolling bearings

Low-friction rolling bearings from Schaeffler already offer the potential for energy savings and a reduction in TCO. Among these are tapered roller bearings with optimized rib contact and a further improved raceway surface structure.

Significant savings can be achieved with optimized high-performance bearings in hydraulic motors and pumps in wheel loaders, for example. Extrapolated to 1,000 construction machines with eight hours of operating time, the annual savings potential is around 26,000 MWh, which corresponds to the average annual energy consumption of more than 6,500 three-person households.

www.schaeffler.com

Powered by

Induportals Media Publishing

machineryasia

machineryasia