Schaeffler Advances Sustainable Mobility with Innovative E-Axle Systems

Optimized Rib Contact, Surface Structures, and Bearing Geometry Reduce Friction in Drivetrains and Hydraulic Pumps. www.schaeffler.com By their very nature, rolling bearings are particularly low friction. However, in cylindrical and tapered roller bearings, there are sliding contacts that cause a high percentage of their frictional torque. Schaeffler’s development engineers have now been able to substantially reduce this proportion even more through targeted optimization measures. Low-friction cylindrical roller bearings There are various applications for cylindrical roller bearings in construction machinery. Accordingly, cylindrical roller bearings can be ideal for use in integrated planetary gear bearing arrangements. Here especially, they offer a major advantage in applications with minimal installation space and high radial load, and thanks to reduced friction can have a direct impact on the necessary energy consumption and thus the emissions of construction machinery. Moreover, cylindrical roller bearings can substantially reduce the energy consumption of hydraulic pumps. Schaeffler engineers presented a use case where low-friction cylindrical and tapered roller bearings were used in the hydraulic system of a 140 kW wheel loader. The result in this case is that up to 9 kW can be saved by using X-life components and bearings with a hydraulic pump optimized in this way and two hydraulic motors. In the case of a fleet of 1,000 wheel loaders with normal operating times, 16,000 metric tons of CO2 can be saved a year. Low-friction tapered roller bearings Whereas conventional tapered roller bearings are already low friction, tapered roller bearings in X-life quality offer an additional increase in energy efficiency and load capacity. The rib contacts of the tapered roller bearings were optimized, while the surface structure, dimensional and running accuracy and material quality were substantially improved. The result is an increase in dynamic load ratings by up to 25 percent, which is associated with a doubling of service life. At the same, the frictional torque is reduced by up to 75 percent, compared with conventional products. These improvements also result in a significant reduction in the noise of the tapered roller bearings. In addition, targeted measures like an application-specific optimized internal geometry achieve reductions in friction that surpass the X-life quality. www.schaeffler.com Powered by Induportals Media Publishing

Optimized Rib Contact, Surface Structures, and Bearing Geometry Reduce Friction in Drivetrains and Hydraulic Pumps.

www.schaeffler.com

By their very nature, rolling bearings are particularly low friction. However, in cylindrical and tapered roller bearings, there are sliding contacts that cause a high percentage of their frictional torque. Schaeffler’s development engineers have now been able to substantially reduce this proportion even more through targeted optimization measures.

Low-friction cylindrical roller bearings

There are various applications for cylindrical roller bearings in construction machinery. Accordingly, cylindrical roller bearings can be ideal for use in integrated planetary gear bearing arrangements. Here especially, they offer a major advantage in applications with minimal installation space and high radial load, and thanks to reduced friction can have a direct impact on the necessary energy consumption and thus the emissions of construction machinery.

Moreover, cylindrical roller bearings can substantially reduce the energy consumption of hydraulic pumps. Schaeffler engineers presented a use case where low-friction cylindrical and tapered roller bearings were used in the hydraulic system of a 140 kW wheel loader. The result in this case is that up to 9 kW can be saved by using X-life components and bearings with a hydraulic pump optimized in this way and two hydraulic motors. In the case of a fleet of 1,000 wheel loaders with normal operating times, 16,000 metric tons of CO2 can be saved a year.

Low-friction tapered roller bearings

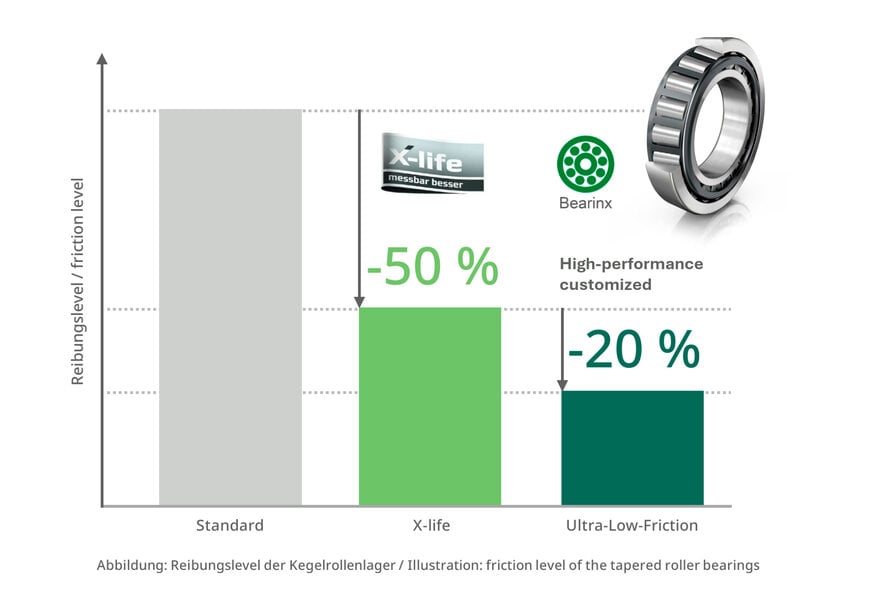

Whereas conventional tapered roller bearings are already low friction, tapered roller bearings in X-life quality offer an additional increase in energy efficiency and load capacity. The rib contacts of the tapered roller bearings were optimized, while the surface structure, dimensional and running accuracy and material quality were substantially improved. The result is an increase in dynamic load ratings by up to 25 percent, which is associated with a doubling of service life. At the same, the frictional torque is reduced by up to 75 percent, compared with conventional products. These improvements also result in a significant reduction in the noise of the tapered roller bearings. In addition, targeted measures like an application-specific optimized internal geometry achieve reductions in friction that surpass the X-life quality.

www.schaeffler.com

Powered by

Induportals Media Publishing

machineryasia

machineryasia