How To Load Equipment on a Trailer

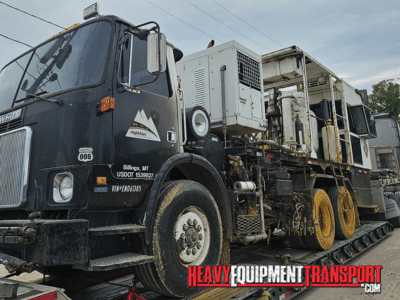

This guide explains how to load equipment on a trailer safely and why many logistics professionals rely on Heavy Equipment Transport for safe and compliant hauling. The post How To Load Equipment on a Trailer appeared first on Heavy Equipment Transport.

How to Load Equipment on a Trailer

The world’s construction market was valued at a staggering $11.39 trillion USD in 2024. This figure is expected to climb to $16.11 trillion USD by 2030. This explosive growth can only be enabled by a robust supply of heavy equipment, such as dozers, cranes, and forklifts. But here’s the thing. Moving heavy equipment is risky business. All it takes is one wrong angle, a slight miscalculation, or a poorly balanced load to turn a routine operation into a catastrophe. Accidents involving heavy equipment cause people to get hurt and businesses to go bankrupt. Knowing how to properly handle heavy machinery loads is a key skill for heavy equipment transporters.

This guide explains how to load equipment on a trailer safely and why many logistics professionals rely on Heavy Equipment Transport for safe and compliant hauling.

Why Proper Trailer Equipment Loading Matters

“Loading errors directly result in reloading costs, delayed shipments and downtimes.“

Maintaining a proper center of gravity during loading prevents load shifts and rollover risk during hauls. Drivers sometimes have to apply sudden braking. If the centre of gravity is too high, it can cause the machinery to drift and topple. In some cases, the inertia is too high, and a poorly secured load can smash through the driver’s cabin.

Weight distribution across the axles is equally critical. This is especially important for heavier loads, where the trailer’s stability is at a greater risk. Suppose if the weight of the equipment is concentrated to the right side of the trailer, and if the driver makes a sharp left, the inertia will cause the equipment to topple over. Optimal weight distribution helps carriers comply with the Department of Transportation’s (DOT) regulations and prevent costly violations.

Loading errors directly result in reloading costs, delayed shipments and downtimes. Heavy Equipment Transport’s certified specialists, trained in heavy haul safety, ensure safe and compliant loading across a variety of trailer types.

Transport Your Containers Today

Heavy Equipment Transport is always available for a quote. Fill out the form or give us a call now! (888) 730-2951

Assessing Your Equipment Before Trailer Loading

A critical piece of a logistician’s job is to assess each piece of equipment before loading. They need to verify the weight, width, height and length of each load. Mechanically inspect to verify the brake, tracks, and hydraulic conditions before each trip. Additionally, make sure to secure each attachment. Replace any harness/safety cable that seems damaged or weak. Also, note any oversize/overweight equipment that may affect trailer choice and the type of permit needed.

Our trained and experienced specialists assess equipment dimensions and recommend the right equipment securement and trailer for the job. Furthermore, we advise on the right permits to seek. Making your operation smooth and compliant.

Choosing the Right Trailer for Safe Equipment Loading

Equipment dimensions are immensely variable. You could be transporting anything from heavy iron blocks to tall equipment like cranes. That’s why selecting the right type of trailer to accommodate each is essential. Choosing the right type depends on equipment characteristics such as height clearance, loading angle and axle capacity. A few commonly used trailer types include:

1. Flatbed Trailers

High-deck versatile trailers are used for standard cargo like lumber, pipes and steel beams. Deck height here is roughly 60 inches.

2. Step Deck Trailers

Consists of an upper and lower deck. The upper deck being 60 inches, while the lower deck ranging from 38-42 inches. Primarily used for taller cargo that is taller but not too heavy: Excavators, for instance,

3. Lowboy Trailers

This type of trailer has extremely low deck heights (18-24 inches) and can feature a fixed/removable gooseneck. Chiefly used for heavy and tall equipment that exceeds height limits on other trailers. The types of cargo for these include backhoes and cranes.

4. RGN (Removable Goose Neck) Trailers

Again, features a low deck height (18-24 inches). The added advantage sis that the front detaches to create a drive-on ramp. Useful for loading equipment that cannot be loaded directly from a staging area. Extremely tall or heavy loads like dozers, can benefit due to the added stability.

5. Landoll Trailers

Average deck heights hover between 30-36 inches and feature a hydraulic sliding axle. The deck is tiltable. Particularly useful for rolling equipment, like forklifts and scissor lifts.

Logisticians need to make an informed call while choosing the right deck height and loading angle. Heavy Equipment Transport’s professional services can help advise on the right trailer for the job. We help reduce costs and downtimes by avoiding mistakes that arise from wrong trailer orders.

Trailer Safety Preparation Before Loading

Here are some safety precautions taken before loading:

1. Always park the trailer on level and stable ground. Uneven or sloped ground can cause the trailer to shift, making the deck unstable.

2. Chock the wheels properly. Make sure that a trainer spotter is keeping an eye out for any movement on the truck. Clear signalling and safety protocols should be observed while the work is executed.

3. Clear the landing zone of any debris and obstacles to maintain loading safety guidelines. The point is to ensure that the equipment doesn’t skid or get stuck, during the loading process.

Our specialists are trained on best-in-class safety standards and make sure that your equipment is handled properly so that your business can operate hassle free.

Step-by-Step Process for Loading Equipment on a Trailer

These equipment loading procedures ensure that personnel and equipment are kept safe:

Step 1: Align the equipment with the trailer’s ramps.

Step 2: Secure the ramps and verify that the angle of approach is stable.

Step 3: Once the equipment has been aligned, slowly drive or winch it onto the trailer.

Step 4: Ensure balance by centring the load over the trailer’s axles.

Step 5: Any attachments, such as the excavator bucket or dozer blades, should be lowered. The brakes should be engaged.

Step 6: Shut off the equipment and confirm the final positioning.

Our professional hauling services take the stress off businesses and help minimize risk at low costs.

Trailer Securement Requirements for Heavy Equipment

Heavy equipment has different trailer securement requirements. You’ll need to consider:

1. The number of tie-downs required based on weight class. Generally, the heavier or taller the machinery, the larger the number of tie downs required.

2. Proper knowledge for the use of Grade 70 chains, ratchet binders and anchor points is required to firmly secure equipment. Knowing where to anchor the machinery will reduce the chances of the equipment skidding off due to the inertia during transportation.

3. Most likely, each equipment will have different appendages: booms, buckets, blades, and other articulated components. Secure each of them and make sure they remain within the dimensions of the trailer. If neccessary, oversized permits might be required if the appendage goes beyond the limits.

4. For added stability, cross-chain the equipment and perform tension checks.

We take pride in employing best-in-class safety as part of our loading processes. Our aim is to ensure personnel and load safety during long haul transportation.

Final Trailer Inspection Before Transport

Perform these final inspection checks before your trailer gets dispatched:

1. Re-check tension in your tie-downs after settling.

2. Inspect trailer lights, flags, signs, and OVERSIZE LOAD banners.

3. Verify route clearance for height, weight and any other travel restrictions.

4. Verify that you have all the required permits and paperwork.

Each haul is carefully inspected by our experts so that each journey is made safe, reliable and risk-free.

When to Call a Professional Trailer Loading and Hauling Team

Businesses often struggle when loading heavy equipment in challenging environments. Here are a few instances where you should bring in professionals to handle the job:

1. Oversized/overweight machinery takes experienced and expert trailer handling.

2. Non-running or damaged equipment needs winching and specialty ramps.

3. Tight job sites or uneven terrain increase trailer loading risk.

4. High-value equipment requires professional securement to avoid damage.

In these conditions, partnering with Heavy Equipment Transport reduces risk and prevents expensive loading errors.

FAQs — Loading Equipment on a Trailer

What is the safest way to load heavy equipment onto a trailer?

Secure the trailer. Use a trained spotter. Make sure that the equipment’s centre of gravity is as low as possible.

Which trailer type is best for my equipment?

Depends on the size and weight of each load.

How many tie-downs are required for trailer securement?

Depends on the weight class of your equipment. FMCSA requires a minimum of four tie-downs for equipment over 10,000 pounds

Can I load oversize equipment onto a trailer by myself?

It is recommended to call in qualified and experienced professional loaders for the job.

How does Heavy Equipment Transport ensure safe trailer loading?

Our professionals have years of heavy equipment handling experience. We employ industry best practices coupled with years of refined internal processes to get the job done.

William Thomas

Heavy Transport Specialist

Being able to lead a team of such talented logistics agents has been a wonderful experience over the past ten years. If you would like to know anything more about the heavy equipment transport services we offer, don't hesitate to give us a call!

The post How To Load Equipment on a Trailer appeared first on Heavy Equipment Transport.

machineryasia

machineryasia