Highly flexible flange coupling with progressive torsion spring stiffness

KTR's VAROLASTIC was specially developed for applications with variable load requirements, such as construction and agricultural machines. VAROLASTIC is a sturdy series of highly flexible flange couplings which is a particularly good choice for variable-speed main drives due to their progressive torsional stiffness. Key benefits for reliable power transmission Progressive torsion spring stiffness: The VAROLASTIC adapts to different load conditions and optimises the vibration behaviour to ensure smooth operation. Highly elastic elastomers: The synthetic rubber elastomers ensure optimum damping of torsional vibrations and minimise shocks to protect adjacent components - for temperatures up to 120 °C. Low-wear design: The few components and the sturdy design reduce maintenance effort extending the service life of the overall drive train. Versatile application possibilities: Developed for sophisticated applications in mechanical engineering, the VAROLASTIC convinces by high power density under varying operating conditions. Countless possibilities: Optionally available as an anti-rotation safety device and prepared for being adapted to SAE connections. Short coupling: Thanks to its compact design, the VAROLASTIC can be quickly and easily integrated into existing drives. KTR offers two types of VAROLASTIC flange couplings: standard version "F" and with anti-rotation device "FD". www.ktr.com Powered by Induportals Media Publishing

KTR's VAROLASTIC was specially developed for applications with variable load requirements, such as construction and agricultural machines.

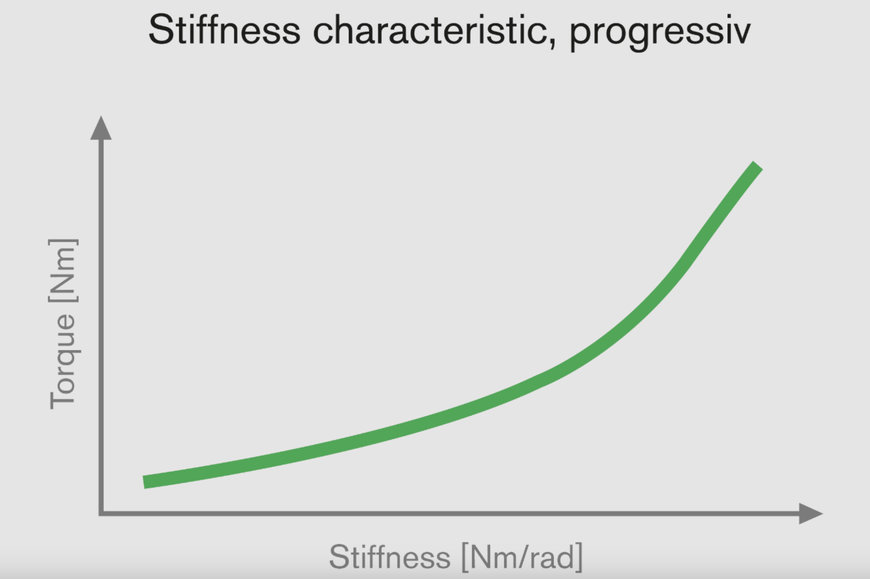

VAROLASTIC is a sturdy series of highly flexible flange couplings which is a particularly good choice for variable-speed main drives due to their progressive torsional stiffness.

Key benefits for reliable power transmission

- Progressive torsion spring stiffness: The VAROLASTIC adapts to different load conditions and optimises the vibration behaviour to ensure smooth operation.

- Highly elastic elastomers: The synthetic rubber elastomers ensure optimum damping of torsional vibrations and minimise shocks to protect adjacent components - for temperatures up to 120 °C.

- Low-wear design: The few components and the sturdy design reduce maintenance effort extending the service life of the overall drive train.

- Versatile application possibilities: Developed for sophisticated applications in mechanical engineering, the VAROLASTIC convinces by high power density under varying operating conditions.

- Countless possibilities: Optionally available as an anti-rotation safety device and prepared for being adapted to SAE connections.

- Short coupling: Thanks to its compact design, the VAROLASTIC can be quickly and easily integrated into existing drives.

KTR offers two types of VAROLASTIC flange couplings: standard version "F" and with anti-rotation device "FD".

Powered by

Induportals Media Publishing

machineryasia

machineryasia