First Volvo EC550E excavators in Middle East live up to expectations

The Middle East and Africa launch of the Volvo EC550E excavator in early 2022 was accompanied by bold claims of up to 35% greater productivity and 22% greater fuel efficiency. www.volvoce.comMembers of the Ashab Alrowad International, Famco, and Volvo teams. Now, almost two years since the first units were delivered to contractor Ashab Alrowad International, these machines have proven their impressive capabilities on a demanding mega project in Saudi Arabia. Alongside the introduction of fully electric machines in UAE, the EC550E excavator with T3 engine from Volvo Construction Equipment (Volvo CE) is one of the most exciting machinery innovations to arrive in the Gulf in recent years. Amid mounting pressures to meet deadlines, control costs, and minimise environmental impact – particularly in Saudi Arabia – the Volvo EC550E demonstrates the ongoing potential of high-performing diesel-powered machines to effectively meet project goals. While offering the advantages of higher productivity, lower fuel consumption, and lower emissions on any mass excavation or large infrastructure project, it can be especially of value to environmentally conscious contractors working in remote areas, where the limitations of grid access currently make electric alternatives impractical. These are benefits contractor Ashab Alrowad International can attest to, having taken delivery of the first Volvo EC550E T3 units in September 2022 for a demanding earthmoving application in north-west Saudi Arabia. Since then, Ashab Alroward International has put the excavators to work with both buckets and breakers on long shifts in hot, dusty conditions and has been impressed with their performance. The company’s owner Hussain Omar praised the Volvo EC550E units’ power, speed, and reliability, which has led him to be ‘very satisfied with the production’. As for the fuel efficiency, Hussain described it as ‘fantastic’ and ‘almost the fuel consumption of the EC480D but with much greater productivity’. He also reported that the operators were ‘very happy with the comfortability’ and found the machines ‘very easy to control’. So how did Volvo engineers manage to combine both exceptional power and fuel efficiency in one high-performance machine? Breaking the link between production and operating weight First, the Volvo EC550E features a larger bucket to deliver up to 25% greater production than the EC480D in typical dig-and-dump applications. This is enabled through the increased undercarriage dimensions for stability, as well as the upgraded structural component dimensions on the frame, boom and arm. It can then achieve a further 10% increase in production over the EC480D due to the faster cycle times, which result from the engine’s high torque at a relatively low rpm combined with large displacement pumps. In fact, the 2071Nm (320kW) engine is well in line with some competitor 70 t machines. In this way, the Volvo EC550E breaks the norm of production output having a direct link to excavator operating weight. An industry first in hydraulic system technology The Volvo EC550E excavator’s 22% greater fuel efficiency over the EC480D, meanwhile, comes from using independent metering valve technology (IMVT) instead of a conventional spool-type main control valve (MCV), which is an industry first in this size class. Oil is pumped exactly according to demand to eliminate hydraulic losses, reduce fuel consumption, and provide the excellent controllability experienced by Ashab Alrowad International’s operators. Long track record for quality and uptime Choosing a machine equipped with innovative systems such as IMVT could seem risky to some contractors who have traditionally relied on proven technologies for completing projects to tight deadlines in harsh environments. However, Ashab Alrowad International had full confidence to place its trust in Volvo and Saudi Arabian dealer FAMCO. Since 2012, the contractor has successfully operated Volvo machines from Famco on numerous road and infrastructure projects, maintaining consistently high uptime. As soon as the Volvo EC550E T3 launch was announced, Ashab Alroward International was eager to be the first construction company to deploy these groundbreaking excavators, drawn by the promises of speed and productivity. Proactive dealer support Famco supplied the Volvo EC550E excavators along with an operator training program to ensure operators could maximize the machines' potential. This training emphasized best practices for fuel-efficient operation, such as minimizing machine idling, selecting the appropriate power mode and using smooth movements, as well as reducing travel speed and choosing the most direct routes. The dealer has also set up a temporary workshop next to Ashab Alrowad International’s jobsite to guarantee the excavators’ availability through regular preventative maintenance and quick intervention from experienced Famco service and repair technicians. The quality and performance of

The Middle East and Africa launch of the Volvo EC550E excavator in early 2022 was accompanied by bold claims of up to 35% greater productivity and 22% greater fuel efficiency.

www.volvoce.com

Now, almost two years since the first units were delivered to contractor Ashab Alrowad International, these machines have proven their impressive capabilities on a demanding mega project in Saudi Arabia.

Alongside the introduction of fully electric machines in UAE, the EC550E excavator with T3 engine from Volvo Construction Equipment (Volvo CE) is one of the most exciting machinery innovations to arrive in the Gulf in recent years. Amid mounting pressures to meet deadlines, control costs, and minimise environmental impact – particularly in Saudi Arabia – the Volvo EC550E demonstrates the ongoing potential of high-performing diesel-powered machines to effectively meet project goals.

While offering the advantages of higher productivity, lower fuel consumption, and lower emissions on any mass excavation or large infrastructure project, it can be especially of value to environmentally conscious contractors working in remote areas, where the limitations of grid access currently make electric alternatives impractical. These are benefits contractor Ashab Alrowad International can attest to, having taken delivery of the first Volvo EC550E T3 units in September 2022 for a demanding earthmoving application in north-west Saudi Arabia.

Since then, Ashab Alroward International has put the excavators to work with both buckets and breakers on long shifts in hot, dusty conditions and has been impressed with their performance. The company’s owner Hussain Omar praised the Volvo EC550E units’ power, speed, and reliability, which has led him to be ‘very satisfied with the production’.

As for the fuel efficiency, Hussain described it as ‘fantastic’ and ‘almost the fuel consumption of the EC480D but with much greater productivity’. He also reported that the operators were ‘very happy with the comfortability’ and found the machines ‘very easy to control’.

So how did Volvo engineers manage to combine both exceptional power and fuel efficiency in one high-performance machine?

Breaking the link between production and operating weight

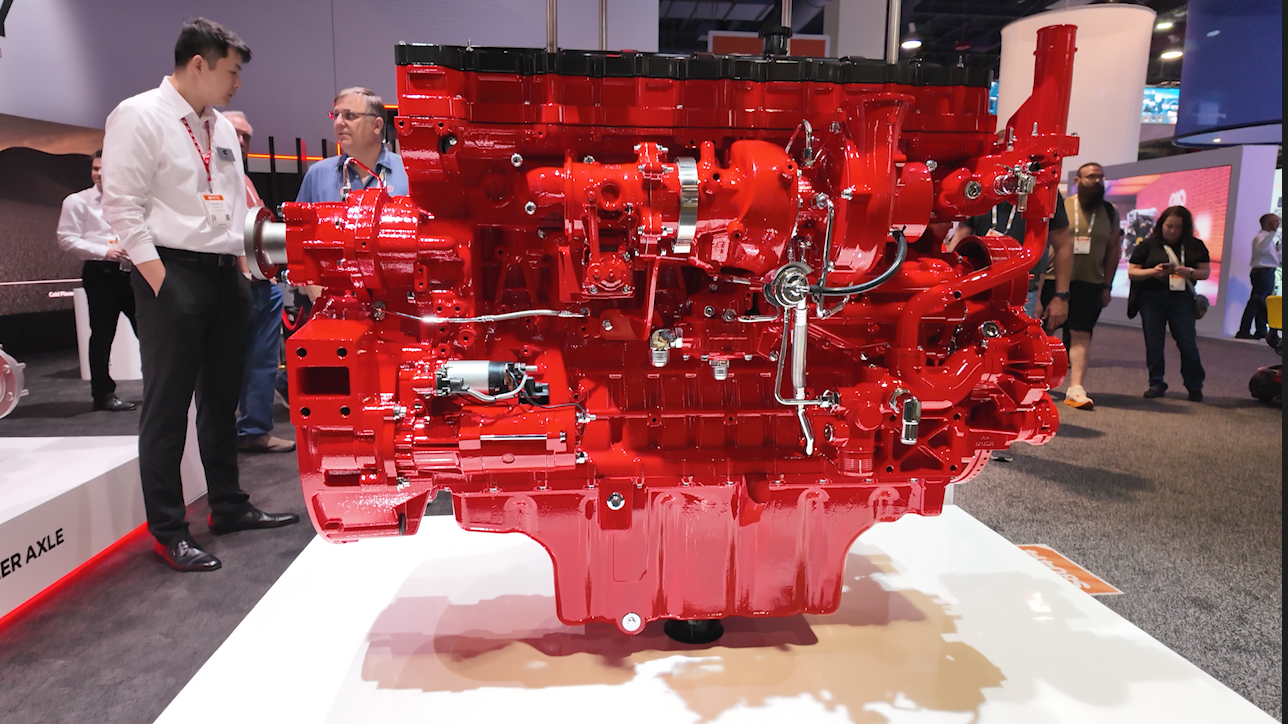

First, the Volvo EC550E features a larger bucket to deliver up to 25% greater production than the EC480D in typical dig-and-dump applications. This is enabled through the increased undercarriage dimensions for stability, as well as the upgraded structural component dimensions on the frame, boom and arm. It can then achieve a further 10% increase in production over the EC480D due to the faster cycle times, which result from the engine’s high torque at a relatively low rpm combined with large displacement pumps. In fact, the 2071Nm (320kW) engine is well in line with some competitor 70 t machines. In this way, the Volvo EC550E breaks the norm of production output having a direct link to excavator operating weight.

An industry first in hydraulic system technology

The Volvo EC550E excavator’s 22% greater fuel efficiency over the EC480D, meanwhile, comes from using independent metering valve technology (IMVT) instead of a conventional spool-type main control valve (MCV), which is an industry first in this size class. Oil is pumped exactly according to demand to eliminate hydraulic losses, reduce fuel consumption, and provide the excellent controllability experienced by Ashab Alrowad International’s operators.

Long track record for quality and uptime

Choosing a machine equipped with innovative systems such as IMVT could seem risky to some contractors who have traditionally relied on proven technologies for completing projects to tight deadlines in harsh environments. However, Ashab Alrowad International had full confidence to place its trust in Volvo and Saudi Arabian dealer FAMCO. Since 2012, the contractor has successfully operated Volvo machines from Famco on numerous road and infrastructure projects, maintaining consistently high uptime. As soon as the Volvo EC550E T3 launch was announced, Ashab Alroward International was eager to be the first construction company to deploy these groundbreaking excavators, drawn by the promises of speed and productivity.

Proactive dealer support

Famco supplied the Volvo EC550E excavators along with an operator training program to ensure operators could maximize the machines' potential. This training emphasized best practices for fuel-efficient operation, such as minimizing machine idling, selecting the appropriate power mode and using smooth movements, as well as reducing travel speed and choosing the most direct routes. The dealer has also set up a temporary workshop next to Ashab Alrowad International’s jobsite to guarantee the excavators’ availability through regular preventative maintenance and quick intervention from experienced Famco service and repair technicians.

The quality and performance of the Volvo EC550E excavators, backed by Famco’s aftermarket support, has more than lived up to Ashab Alrowad International’s expectations, helping the company to meet targets on a major project in Saudi Arabia. Owner Hussain Omar said he would strongly recommend the Volvo EC550E which, with its robust design and innovative technology, is contributing to highly productive and more sustainable construction in the region.

www.volvoce.com

Powered by

Induportals Media Publishing

machineryasia

machineryasia