Danfoss Power Solutions Advances Electrification & Track Drive Design

The Editron ED3 onboard charger and Thorx CLM 12 T cam lobe motor, developed for modern agricultural machinery, earned industry recognition in the 2026 AE50 Awards. www.danfoss.com Agricultural machinery design and off-highway vehicle engineering continue to evolve as manufacturers integrate electrification and more efficient drivetrain technologies. Danfoss Power Solutions has received recognition in the 2026 AE50 Awards, with two of its products acknowledged for their engineering contribution to agricultural equipment developed during 2025. The AE50 Awards program, sponsored by the American Society of Agricultural and Biological Engineers, annually recognizes innovations across agricultural, food, and biological systems. Awarded technologies demonstrate measurable engineering advancement and relevance for machinery manufacturers and end users, covering components, systems, software, and services. High-power onboard charging for electrified machinery One of the recognized products is a bidirectional onboard charger and electric power supply designed for both off-highway equipment and on-highway commercial vehicles. The system supports high-power charging from standard utility connections and can distribute energy to auxiliary vehicle functions. Rated at 44 kW, the charger provides higher onboard charging capacity than the commonly deployed 22 kW systems, enabling shorter charging cycles and reduced machine downtime. In addition to charging the main high-voltage battery, the unit can supply AC or DC power to subsystems via integrated electric power take-off functionality. By combining AC charging, DC ePTO, and AC ePTO into a single device, the design reduces system complexity and simplifies machine integration. According to Danfoss Power Solutions, the award highlights the role of high-power onboard charging in enabling practical electrification within agricultural applications, where operating availability and charging infrastructure remain critical constraints. Cam lobe hydraulic motor optimized for tracked machines The second recognized product is a hydraulic motor based on cam lobe technology, developed for rubber track drive systems used in machines such as compact track loaders. The motor features a symmetrical architecture that improves packaging efficiency and contributes to extended service life. By positioning the rotating flange at the center of the motor, the design remains within the track width and avoids inward protrusions that typically require structural frame modifications. Load distribution is supported by two tapered roller bearings located near the rotating flange, reducing bending forces during operation. In addition, the rotary group incorporates a higher piston count than comparable motors, lowering contact stress on the cam surface and supporting durability under continuous load. The design addresses long-standing challenges associated with cam lobe motors, particularly installation constraints and bearing life, while maintaining the high-speed efficiency that makes this technology suitable for tracked agricultural equipment. Relevance to evolving agricultural machinery The recognition of both products reflects parallel trends in agricultural engineering: increasing electrification of auxiliary and propulsion systems, and continued optimization of hydraulic drivetrains for durability and efficiency. As tracked vehicles and electrically assisted machinery gain importance in agricultural operations, technologies that reduce downtime, simplify integration, and extend service life play a growing role in equipment design. The AE50 Awards acknowledgment places these developments among notable engineering advances contributing to the next generation of agricultural machinery. www.danfoss.com Powered by Induportals Media Publishing

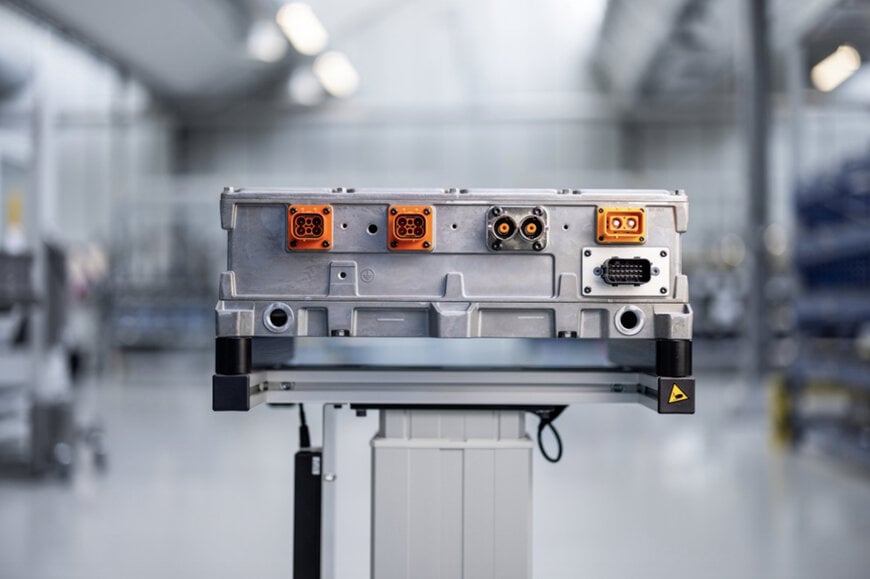

The Editron ED3 onboard charger and Thorx CLM 12 T cam lobe motor, developed for modern agricultural machinery, earned industry recognition in the 2026 AE50 Awards.

www.danfoss.com

Agricultural machinery design and off-highway vehicle engineering continue to evolve as manufacturers integrate electrification and more efficient drivetrain technologies. Danfoss Power Solutions has received recognition in the 2026 AE50 Awards, with two of its products acknowledged for their engineering contribution to agricultural equipment developed during 2025.

The AE50 Awards program, sponsored by the American Society of Agricultural and Biological Engineers, annually recognizes innovations across agricultural, food, and biological systems. Awarded technologies demonstrate measurable engineering advancement and relevance for machinery manufacturers and end users, covering components, systems, software, and services.

High-power onboard charging for electrified machinery

One of the recognized products is a bidirectional onboard charger and electric power supply designed for both off-highway equipment and on-highway commercial vehicles. The system supports high-power charging from standard utility connections and can distribute energy to auxiliary vehicle functions.

Rated at 44 kW, the charger provides higher onboard charging capacity than the commonly deployed 22 kW systems, enabling shorter charging cycles and reduced machine downtime. In addition to charging the main high-voltage battery, the unit can supply AC or DC power to subsystems via integrated electric power take-off functionality. By combining AC charging, DC ePTO, and AC ePTO into a single device, the design reduces system complexity and simplifies machine integration.

According to Danfoss Power Solutions, the award highlights the role of high-power onboard charging in enabling practical electrification within agricultural applications, where operating availability and charging infrastructure remain critical constraints.

Cam lobe hydraulic motor optimized for tracked machines

The second recognized product is a hydraulic motor based on cam lobe technology, developed for rubber track drive systems used in machines such as compact track loaders. The motor features a symmetrical architecture that improves packaging efficiency and contributes to extended service life.

By positioning the rotating flange at the center of the motor, the design remains within the track width and avoids inward protrusions that typically require structural frame modifications. Load distribution is supported by two tapered roller bearings located near the rotating flange, reducing bending forces during operation. In addition, the rotary group incorporates a higher piston count than comparable motors, lowering contact stress on the cam surface and supporting durability under continuous load.

The design addresses long-standing challenges associated with cam lobe motors, particularly installation constraints and bearing life, while maintaining the high-speed efficiency that makes this technology suitable for tracked agricultural equipment.

Relevance to evolving agricultural machinery

The recognition of both products reflects parallel trends in agricultural engineering: increasing electrification of auxiliary and propulsion systems, and continued optimization of hydraulic drivetrains for durability and efficiency. As tracked vehicles and electrically assisted machinery gain importance in agricultural operations, technologies that reduce downtime, simplify integration, and extend service life play a growing role in equipment design.

The AE50 Awards acknowledgment places these developments among notable engineering advances contributing to the next generation of agricultural machinery.

www.danfoss.com

Powered by

Induportals Media Publishing

machineryasia

machineryasia